Caterpillar, Stage V, and the C9.3B

Caterpillar at the dawn of Stage V Caterpillar is working hard on its Stage V engine range. Productivity, energy efficiency, and power density are the keywords ruling Cat’s industrial products, from the two-cylinder C0.5 to the 32 cylinders of the C32 engine. Stage V-compliant strategy includes developing more efficient post-treatment systems and simplified installation procedures for OEMs. The […]

Caterpillar at the dawn of Stage V

Caterpillar is working hard on its Stage V engine range. Productivity, energy efficiency, and power density are the keywords ruling Cat’s industrial products, from the two-cylinder C0.5 to the 32 cylinders of the C32 engine. Stage V-compliant strategy includes developing more efficient post-treatment systems and simplified installation procedures for OEMs.

The time of the C9.3B

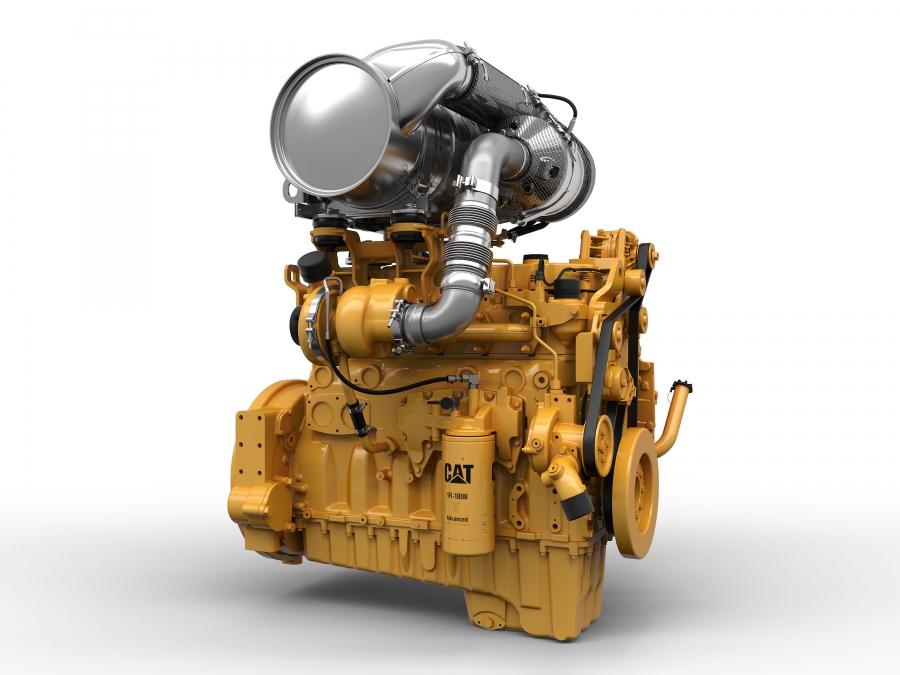

For example, the Cat C9.3B, designed to meet Stage V regulations, is now in production. It means Cat has moved far in advance of the latest and most stringent regulatory requirements in the industry. Jeff Moore, product director, research and development for 7.2 to 18 liters engines, commented on the result. «The C9.3B’s certification is an exciting milestone for Caterpillar. We’re confident that this engine will meet customer expectations for reliability and durability in a simpler, lighter package with more power and torque. Caterpillar has proven the merits of the C9.3B by testing the engine to its limits, both in the lab environment and in actual customer applications».

The 9.3-liter six-cylinder C9.3B shares the same architecture of the previous (since 2011) production line. Over the years, it has recorded over 200 million hours of off-road operation in the real world. With a proven and reliable base engine, coupled with extensive Dpf experience, Caterpillar has focused the development of Stage V on simplifying the design. Also performances and ease of installation improved.

The C9.3B combines a new high pressure/common rail fuel system with simplified air, electricity, and aftertreatment systems. The mix promises to provide up to 340 kilowatts and 2088 newton meters. Translated, 18 percent more power, 21 percent more torque and 12 percent less weight than its predecessor. Like all Cat engines from 9 to 18 liters, C9.3B is available in various configurations. These include those with radiators and factory-installed after-treatment systems. In total, over 2,000 configurations are available for the C9.3B.

Cat works for OEMs, says Jeff Moore

«End users will see this refinement pay off with increased performance, up to 3 percent less fuel consumption and exceptional starting capability in cold climates», says Moore. «Patented after-treatment technology provides a compact, lightweight design that is 39 percent smaller and 55 percent lighter than the EU Stage IV/Tier 4 Final configuration. The new design provides transparent regeneration to ensure optimum machine performance and uptime».

«We understand that not all customers have the resources to design, manufacture, and validate on the same scale», says Moore. «For that reason, Caterpillar designs its products with the flexibility to accommodate various OEM requirements, resulting in lower installation costs».

An entire range on the way to Stage V

In addition to the C9.3B, the large Cat Stage V range also includes the 12.5-liter C13B. This uses technology similar to that of the C9.3B and features powers up to 430 kW. Caterpillar is also driving the C13, C15, and C18 to Stage V / Epa Tier 4-Final. The Stage V certification for these engines will be achieved without changes to the customer interface and with minimal modifications to the Dpf. Cat engines and Dpf solutions in this range have nearly 170 million hours of proven performance on the field.

Caterpillar will start accepting orders for Stage V engines from C13 to C18 in May. The company plans to begin shipping in October. The C13B will be available in 2019. The double Stage V/Epa Tier 4-Final certification (including Japan and Korea) will be available for the C9.3B. All other Cat products in the power range from 250 to 597 kW will also be included.