mtu for Newton Trucks

Newton Trucks made its debut at Bauma 2022 and Samoter 2023. An Italian manufacturer bringing back the Perlini 131.33 concept with its steered rear axles. Engines entrusted to the OM 471 and OM 473. It is no coincidence that the company team includes Isabella Perlini, heir to the family tradition

Powered by mtu Newton Trucks appeared at Bauma 2022. A year has now passed and the Italian company based in Padua, Veneto, has aroused the curiosity of those in the industry. An audience always interested to versatility, new and original solutions and low running costs. The Italian OEM is now on the market with three different models. The Net.36, the Net.45 and the Net.72.Acronyms that identify three different load capacity levels with 40 tonnes, 50 tonnes and 65 tonnes. They are distributed on 3- and 4-axle chassis with 6×6, 8×6 and 8×8 all-wheel drive with automatic transmission equipped with torque converter. In the 6×6 version we have the two steered rear axles and in the 8×6 and 8×8 versions the last three are steered.

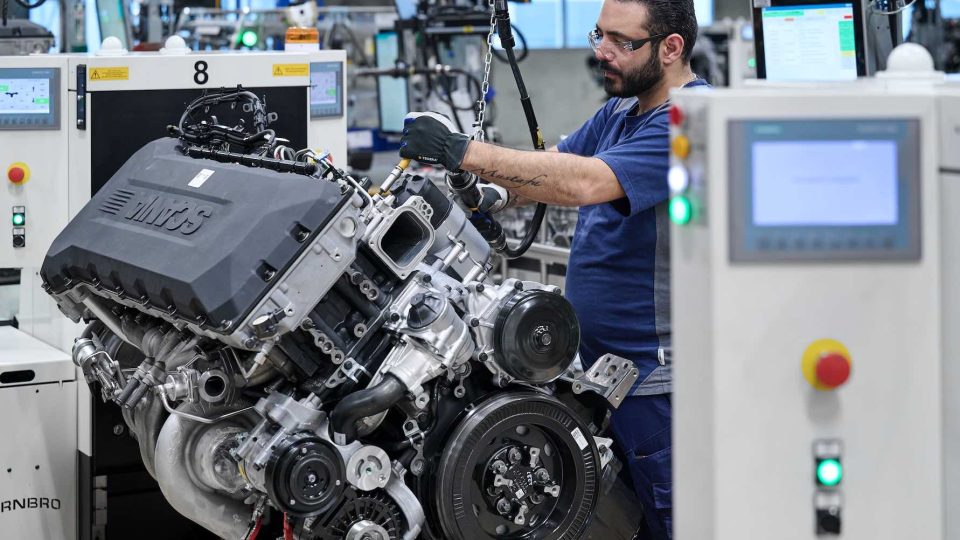

Newton Trucks likes mtu engines

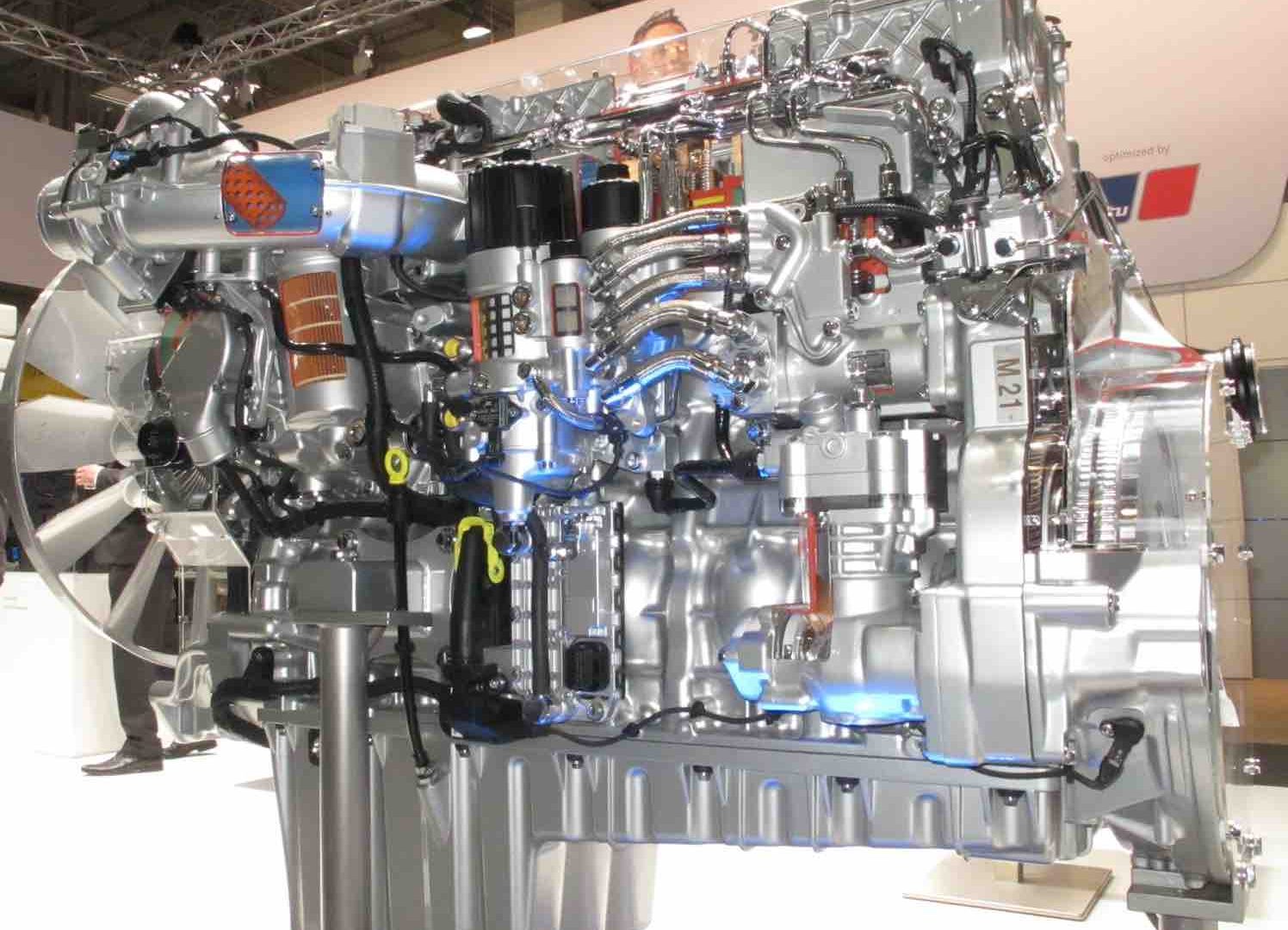

The Italian OEM has an agreement still in place with Rolls-Royce Power Systems for the supply of a couple of engines. The Daimler’s tradition with road applications is well known, moreover with the dual homologation of the propulsion units, Euro 6 with Mercedes, Stage V with mtu. A collaboration that covers the mtu portfolio on a broad spectrum. These are specifically the OM471LA (alias 6R1300) Stage V 350 kW (476 hp) and 12.8 litres (AxC 132×156 mm) for the NET.36. The NET.45, on the other hand, goes up to 365 kW (496 hp) calibration. The NET.72 goes up in displacement to the 450 kW (612 hp) OM473LA Stage V with 15.6 litres (AxC 139×171 mm).

Powertrain

The transmission, as mentioned, is automatic. In the 40- and 50-tonne capacity models we have a 7-speed ZF Ecolife with hydraulic retarder. In the top model with 8×8 all-wheel drive and 65-tonne load capacity, on the other hand, we have a knowledge well known to those who use large articulated and rigid quarry dump trucks. In fact, we are talking about the Allison 4700 R automatic transmission that in fact equips all off-road vehicles in this weight class. The suspension is instead classic independent on the two ‘smaller’ models while we have oil-nitrogen fork suspension on the top machine. The pnematics are also suitable for use. With E4 radials in size 20.5 R 25 in the NET.36 and NET.45 with the alternative, on the latter, of 18.5 R 25. The NET.72 goes up in size with 23.5 R 25 radials. The braking system is instead composed of septum disc brakes with ABS on the two smaller machines and oil-bath disc brakes on the vehicle with the highest load capacity.

The Newton Trucks approach

At the heart of the Veneto-based manufacturer’s philosophy is the fundamental concept of multi-purpose application. Achieved thanks to agility, a cab that is completely comparable to that of ordinary truck but with greater loading capacity. With the aim to represent a valid alternative to articulated dump trucks. These specialised machines are in a high market segment where the purchase cost has a significant influence on the total cost of ownership. The body capacities of the three models available in the Newton Trucks range are 23 m³, 28 m³ and 34 m³. Hardox 500 steel is used for their construction.

Enthusiasts and experts will surely have recognised an old acquaintance in the basic layout of Newton Trucks vehicles. We are talking about the Perlini 131.33, a vehicle that has written important pages of history and can still be seen in action today in many quarries across the boot. The Newton Trucks team also includes Isabella Perlini, heir to the tradition of Officine Meccaniche Perlini.