Rolls-Royce commissions test bench for mtu hydrogen engines

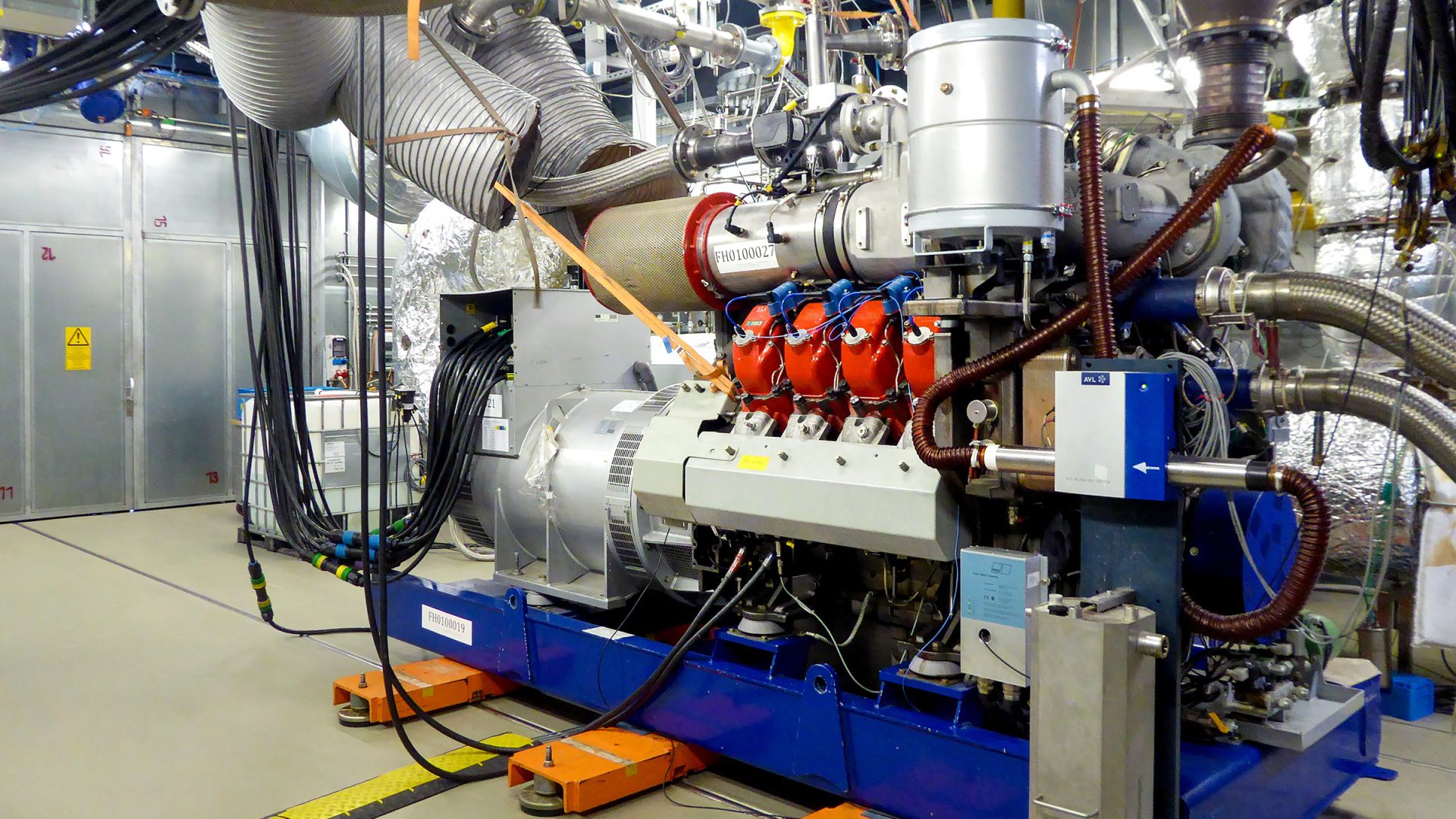

Rolls-Royce has commissioned its first in-house test stand for mtu hydrogen engines at its Augsburg site. “This marks another milestone on the road to climate-neutral products for energy supply,” explained Andreas Schell, CEO of Rolls-Royce’s Power Systems division, during the official commissioning in Augsburg.

Rolls-Royce has commissioned its first in-house test stand for mtu hydrogen engines at its Augsburg site. “This marks another milestone on the road to climate-neutral products for energy supply,” explained Andreas Schell, CEO of Rolls-Royce’s Power Systems division, during the official commissioning in Augsburg. Over the past year and a half, the company has invested around ten million euros at Rolls-Royce Solutions in Augsburg in test bench modernization, hydrogen infrastructure and other measures as part of its “Net Zero at Power Systems” climate protection program.

Rolls-Royce had announced in 2021, as part of its “Net Zero at Power Systems” sustainability program, that it would realign its product portfolio so that by 2030, sustainable fuels and new mtu technologies can achieve greenhouse gas emissions reduction of 35 percent compared to 2019. The company is now already successfully operating an mtu fuel cell system, has released its power generation gensets for sustainable fuels such as HVO (hydrotreated vegetable oils), and is developing electrolyzers to produce green hydrogen. The mtu gas engine portfolio is being prepared for hydrogen as a fuel, thus enabling a climate-neutral energy supply.

“To reduce CO2 emissions in electricity supply, renewable, often decentralized, energy sources are needed to generate electrical energy on a much larger scale than today. In conjunction with these renewable sources, we see hydrogen as an essential energy carrier of the future. That is why we are doing everything we can to gradually bring our mtu gensets and CHP units based on the Series 500 and 4000 gas engines to market for operation with a hydrogen blending of 25 percent by volume (H2) and more and for operation with up to 100 percent by volume,” said Otto Preiss, Rolls-Royce Power Systems Chief Technology Officer and COO.

The Power Systems division of Rolls-Royce has set itself strict targets for reducing greenhouse gas emissions in its own operations as part of its climate protection program: with ambitious interim targets for 2030, the company aims to be climate neutral worldwide by 2050, and in Germany as early as 2045. “The environmental protection measures now implemented at Rolls-Royce Solutions in Augsburg will benefit both the company and the city of Augsburg,” explained Tobias Schnell, Managing Director of Rolls-Royce Solutions Augsburg. These included, for example, feeding residual industrial electricity into the public grid or using waste heat from the test stands to air-condition buildings. At the Augsburg site, (bio-)gas engines and, in the future, hydrogen engines are developed and tested, and gas engine-based systems are built and maintained, which are used, for example, in combined heat and power plants to generate electricity and heat.