Ufi Filters. First European thermal management facility

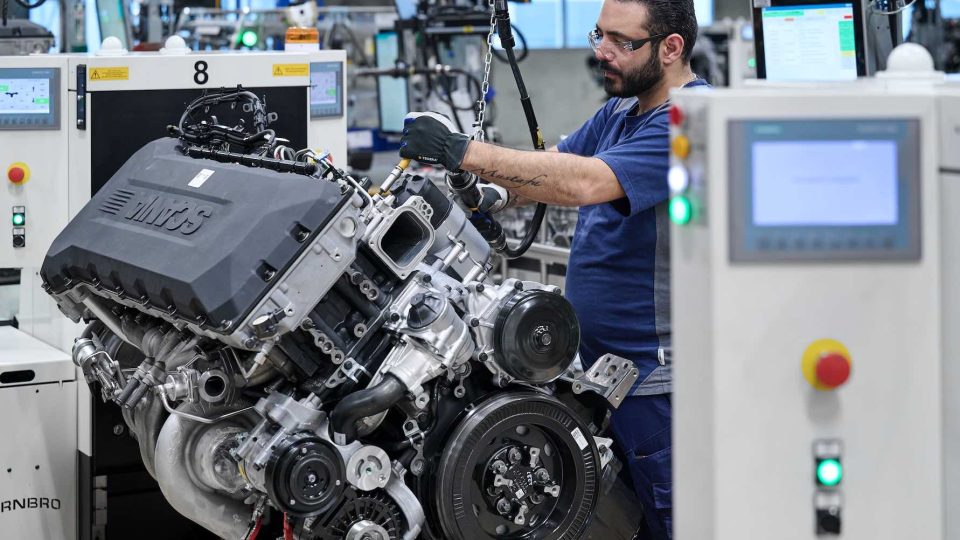

Ufi Filters inaugurated its first European facility dedicated to thermal management Ufi Filters recently inaugurated a new thermal management plant in Opole, Poland, which will double the company’s overall production capacity in terms of heat exchangers by 2023. The plant, with an initial area of 6,000 m2 and a capacity of one million components a […]

Ufi Filters inaugurated its first European facility dedicated to thermal management

Ufi Filters recently inaugurated a new thermal management plant in Opole, Poland, which will double the company’s overall production capacity in terms of heat exchangers by 2023.

The plant, with an initial area of 6,000 m2 and a capacity of one million components a year, will cover 12,000 m2 and triple the production by 2023.

The use of technologically advanced and fully integrated processes will be useful for the creation of coolers for engines, transmissions and other applications, with a specific focus on hybrid and electric vehicles.

The Opole plant brings significant economic benefits to the region, with a total investment of 42 million złoty (around 10 million euros) and the creation of 250 new jobs in the next five years. This is the first Ufi factory dedicated to the production of heat exchangers outside of China. It is located near the Czech industrial site of Ostrava where Ufi Filters produces and assembles filters. This will ensure a quick and immediate connection between the two locations (less than two hours).

UFI MULTITUBE. A REVOLUTION IN AIR FILTRATION

Giorgio Girondi, President of Ufi Filters Group, said: «In recent years water-cooled heat exchangers for engines, transmissions and other applications have represented an important area of growth for Ufi in the area of original equipment and are perfectly integrated with our activities in the filtration sector. We work hard to serve our local customers more and more efficiently. With the opening of this strategic plant in Poland, we have the opportunity to meet the needs of all the most important vehicle manufacturers in Europe with optimized delivery times».

Great plans for the plant

The advanced heat exchangers produced at the new Opole plant are destined to a variety of markets, including automotive and heavy-duty, tractors and construction machines (on-road and off-road), as well as hybrids, fully electric and fuel cells that anticipate future propulsion systems and e-mobility.

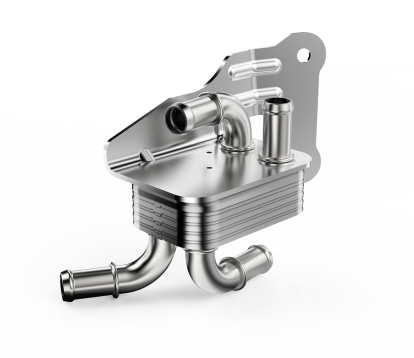

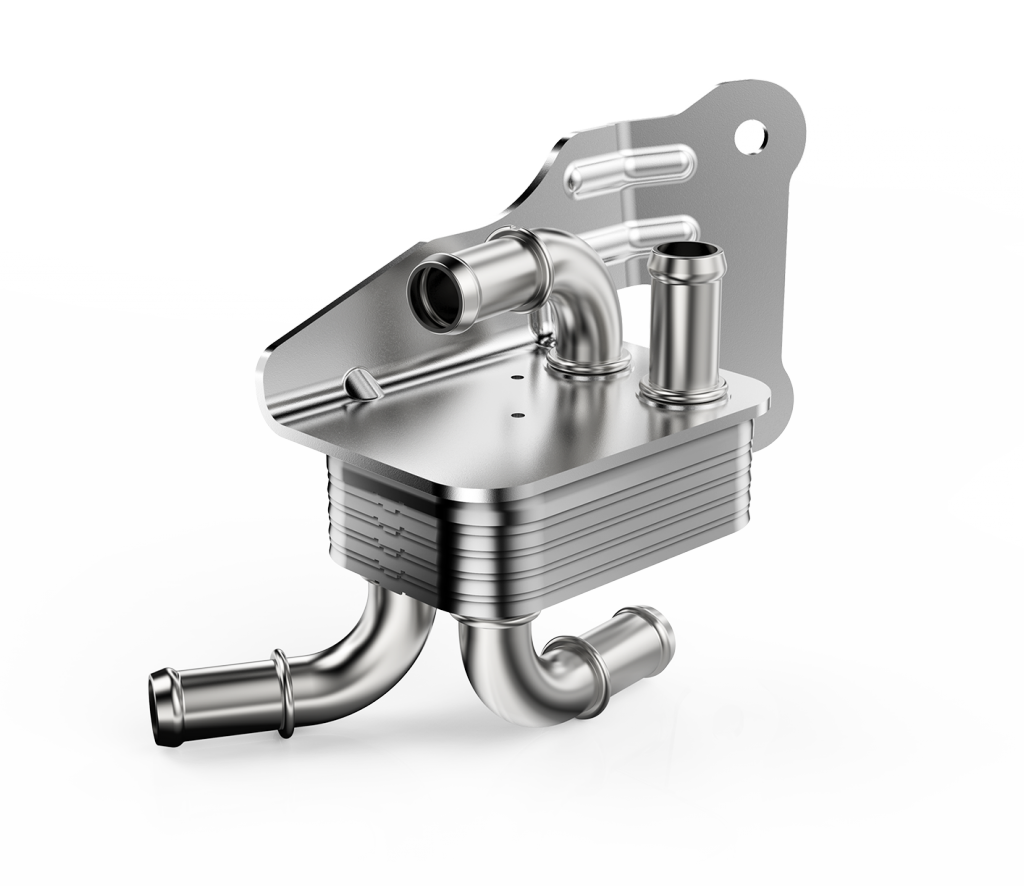

The production processes used in the new plant will enable all Ufi thermal management units to provide the best heat exchangers for engines, transmissions, fuel systems and steering. The Ufi portfolio has recently been expanded with the introduction of battery refrigeration systems. Furthermore, the new plant is equipped with the latest testing and brazing technologies to ensure cleanliness, robustness and reliability.

After entering the field of heat exchangers in 2012, Ufi became a leading company in the development and production of thermal management units. The company is specializing in the field of thermal management technologies and systems integration, combining the production of heat exchangers with integrated additional components including thermostatic, non-return and pressurization valves, coarse mesh filters for refrigerant, sensors and integrated adapter plates.

Giorgio Girondi explained: «As a company experienced in systems innovation and integration, Ufi continues to market new thermal management units that can cool and heat any fluid. The combination of our expertise and the additional capacity now available at the Opole factory allows us to anticipate the requirements for thermal exchange of future propulsion systems and to respond to the growing demand in Europe. In the next few years, the Opole plant will also begin to produce filters, to meet the growing demand of our customers».

The plant will also act as an aftermarket logistics center and it is destined to become an important landmark in the European market.