Eima 2018. Andrea Serra unveils the news from Oerlikon

Welcome to Eima 2018. What are the news from Oerlikon? Compared to Agritechnica, the core of Oerlikon news, presented at Hannover, it’s the same. The structure of the Css didn’t change, but what evolved in the meanwhile is its application, with the cooperation of a pilot customer, that’s covered by non-disclosure at the moment. Oerlikon […]

Welcome to Eima 2018. What are the news from Oerlikon?

Compared to Agritechnica, the core of Oerlikon news, presented at Hannover, it’s the same. The structure of the Css didn’t change, but what evolved in the meanwhile is its application, with the cooperation of a pilot customer, that’s covered by non-disclosure at the moment.

Oerlikon for farmers

Are we talking about a tractor?

Exactly, we are talking about a tractor and we are currently developing prototypes that will start to be tested at the beginning of 2019.

Can you tell us more about this application?

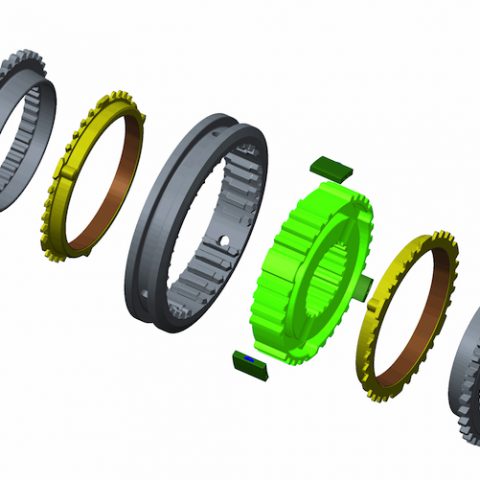

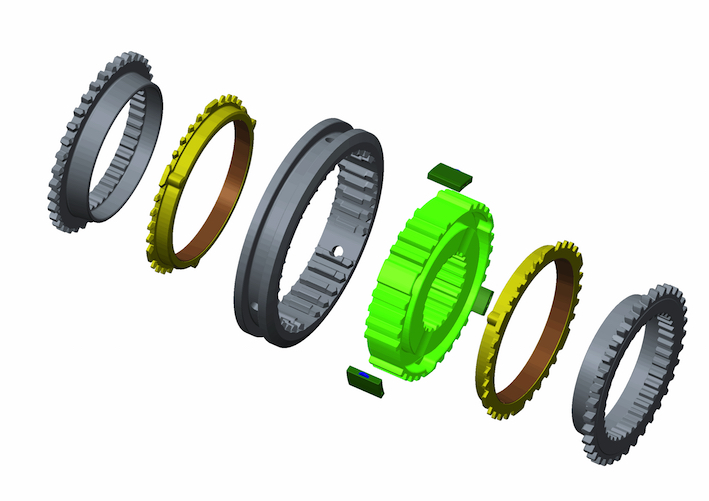

The synchronizer is interchangeable with the standard version of the already available synchronizers size 90 which, in the same space, guarantees superior performances.

The most relevant aspects are, first of all, the power density, that ensures better performancers, given the same dimensions, thanks to wider internal friction surfaces that allow to stress more the friction material without compromising its durability and obtain better performances in terms of shifting time, an innovative element that has been quite appreciated.

The other innovation concerns the long-lasting activation system that has a tangential development unlike the classic activation systems that portrait a radial development instead; this allows for enhanced durability because the new shape allows for a stress that is comparable to the one endured by the best integrated activators on the market (we are talking about one million shifting cycles without ruptures), with much smaller radial dimensions, allowing the installation of the synchronizer on larger shafts. This increases its fields of application, thanks to a more ideal custom fit for the user.

Without pushing on the anonymity of the application, can you tell us what was the reason behind the choice? Is it the power of this tractor?

Yes, I’d say so. It is a top of the range tractor and we are in a very early phase of the development. Towards the beginning of the next year the first new versions of these transmissions will be built to be tested. So we will soon have the first results that will determine the continuation of the development of this new application.

Are there more projects in development?

Another project concerns the triple-cone synchronizer, with three friction surfaces. From the point of view of the internal architecture it is the most classic one, in the sense that it does not have a tangential activator, the novelty lies in the introduction of a triple cone in the world of agricultural machinery.

An approach never explored by anyone before. We have converted towards an operating machine a technology, the one of the triple-cone synchronizer, that is normally used on high-powered cars (sports cars).

Oerlikon and the synchronizers

The driver is always the same: to guarantee satisfactory performances while preserving small dimensions. The synchronizer has a similar size to that of the 90 (actually it is slightly larger: diameter 118): the triple cone allows us to combine the compactness of the dimensions to higher performances. The need for power is a significant requirement in the world of agricultural machinery. This is also a solution in response to the increasing scarcity of space under the bonnet.

Are we talking about a brand new project also in this case?

Yes, even in this case we are talking about an embryonic project that will probably find application in the same areas of the Css.

How long will it take for the incubation and development period?

For a massive production, two or three years of experimentation may still be needed. The development of these innovations, however, is always supported by our customers, who are also primary players in the sector, even if we are talking about a mature market, unlike hybrids and electric.

The synchronizer is a mechanical device that must be able to perform a certain task repeatedly. The goal is to carry out this task always better and with lower costs. So it is a field with limited opportunities for innovation. Those that we introduce can be seen as optimizations, that are necessary to answer to the different requests for compactness and high performance.

OERLIKON AND DANA. THINKING BIG