990K aggregate handler by Cat

990K aggregate handler boosts wheel loader production Caterpillar recently introduced the 990K aggregate handler, designed to handle greater payloads in aggregates yard applications. With as much as a 25 percent payload increase, as compared to the standard 990K, the new aggregate handler enables customers to load trucks and railcars faster. It also allows them to […]

990K aggregate handler boosts wheel loader production

Caterpillar recently introduced the 990K aggregate handler, designed to handle greater payloads in aggregates yard applications. With as much as a 25 percent payload increase, as compared to the standard 990K, the new aggregate handler enables customers to load trucks and railcars faster. It also allows them to move more material in load-and-carry and stockpile management tasks.

The Cat 990K aggregate handler has a payload of 20 tonnes (22 tons) and a full turn static tipping load of 43,738 kg. Additional counterweight maintains machine stability, and 990K structures ensure durability in the aggregate handler configuration.

The 990K is available in standard lift configuration with 13.5-ft (4,108-mm) dump clearance and in high lift configuration with 15-ft (4,569-mm) dump clearance. In particular, increased capacity and high dump clearance enable customers to load railcars and large trucks with a better pass match for faster material handling at lower cost per ton.

Also, the new aggregate handler complements the smaller 986K and 988K aggregate handlers in the Cat large wheel loader line. It is, however, not designed for use in quarry face or other shot rock applications.

CAT 796 AND 798 ULTRA-CLASS TRUCKS

What’s there behind the 990K

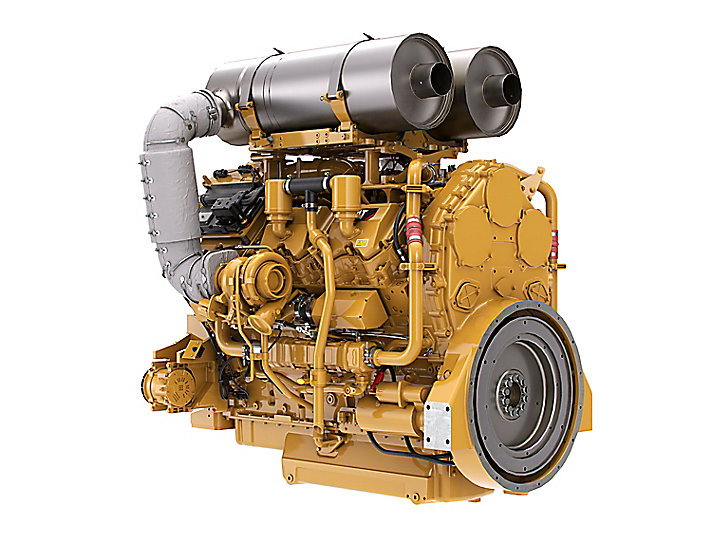

The 990K features got inspiration from the ones of the 990K wheel loader. The 990K powertrain provides powerful operation with higher fuel efficiency. The Cat C27 engine powers the loader and delivers a net power of 521 kW. Lower engine speed helps drive economical fuel use. Additional fuel savings accrue with the Eco Mode (on-demand throttle), engine-idle shutdown system and engine-idle kickdown/auto-resume system.

The Cat exclusive impeller clutch torque converter uses a lock-up clutch, providing direct drive to boost fuel economy, trim cycle times, and reduce heat. Especially in load-and-carry applications. The system allows operators to balance rimpull and hydraulic power in favour of loading efficiency.

Positive Flow Control implement hydraulics use a variable displacement, electronically controlled pump to precisely apportion oil flow. A number of drivetrain options are available. The integrated axle cooling and ride control options are particularly beneficial in load-and-carry work.

Operator-friendly solutions in the ‘package’

The operator station features the Cat Vital Information Management System, Vims 3G. It provides customizable operator profiles, a cycle timer and an integral payload control system, which provides on-the-go payload weighing. The graphical information display keeps key information in front of the operator. Also, the Cat Comfort III seat provides integrated seat-mounted controls for smooth and comfortable operation. Transmission controls allow convenient travel control.

The 990K comes also with the Cat Vision rearview camera system and in-cab display to show the operator the area behind the loader. The Cat Detect object detection system (optional) builds on the camera system with radars and in-cab software that provide notification when an object is within the radar coverage area. The systems aim to enhance operator awareness, especially in congested loading areas.