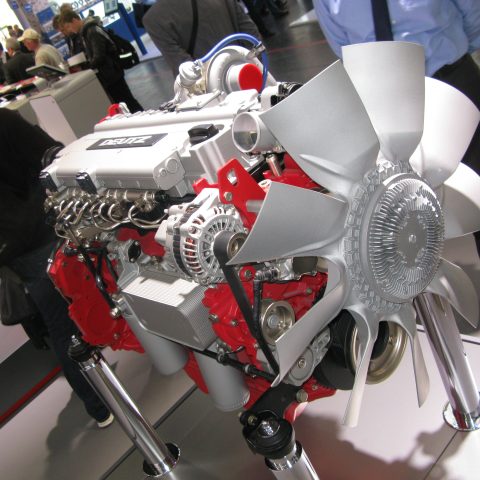

Deutz TCD4.1 for the Liebherr T60-9s

Liebherr has chosen the Deutz TCD 4.1 for the T 60-9S, one of their 12 telehandlers designed primarily for heavy-duty applications

Deutz and Liebherr, an old bond, strengthened by an agreement dating back to 2017. It seems a lifetime ago. The Board of Directors at the time signed a cooperation agreement on spare parts and assistance with the OEM for earthmoving, as well as an engine manufacturer. A partnership that was supposed to relaunch Deutz in the displacement range above 6 liters and which provided for the supply of Cologne’s engines for Liebherr machines.

The 4-cylinder Deutz for the flexible Liebherr telehandler

Regarding internal combustion engines, this collaboration has involved the T 60-9s, a model that, in terms of performance, sits at the top of Liebherr’s telehandler range. In fact, it’s capable of lifting 6 metric tons and operating at a height of 9 meters. This machine is designed for handling large quantities of material.

The Deutz TCD 4.1 delivers 115 kilowatts at 2,300 rpm and 609 Nm at 1,600 rpm. This engine powers the Load Sensing hydraulic system, which provides 200 liters per minute. Following the manufacturer’s core philosophy, the transmission is hydrostatic.

Furthermore, the presence of the “Auto Power” function automatically adjusts the engine speed without changing the travel speed. This allows the operator to concentrate on maneuvers, optimizing work times and safety without having to worry about operational speed aspects.

Serving Jüly Abfallservice for waste and beyond

Jüly Abfallservice is a family-run company based in Austria. It’s a classic example of a business that, since its founding in 1955, has evolved from a farm specializing in sludge pumping into a modern waste disposal company. Today, thanks to continuous innovation, a technological vision, and a commitment to sustainability, it makes a significant contribution to waste disposal from its headquarters in Bruck an der Leitha, midway between Vienna and Bratislava.

The company uses Liebherr telehandlers as their primary machines to manage all logistical activities at their company headquarters. These tasks involve handling sharp metallic materials, points, and other sharp objects found on the recovery and recycling platform. Such materials, moreover, cause rapid tire wear. For this reason, all telehandlers at the company are equipped with solid rubber tires.

The telehandler operates year-round in various waste loading, sorting, and compacting operations. In addition, the Liebherr T 60-9s also handles the loading and unloading of containers using its forks. For waste management companies, space optimization is crucial. This is why telehandlers are essential machines, thanks to their all-wheel steering which reduces operational space requirements.