In Italy the first gas cogenerator with a Scania engine

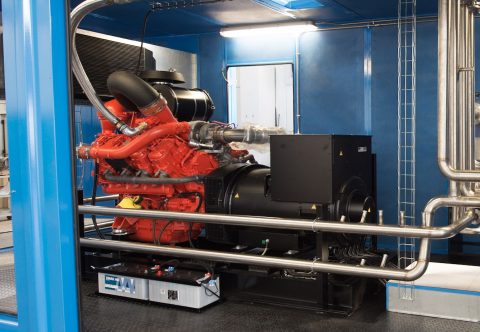

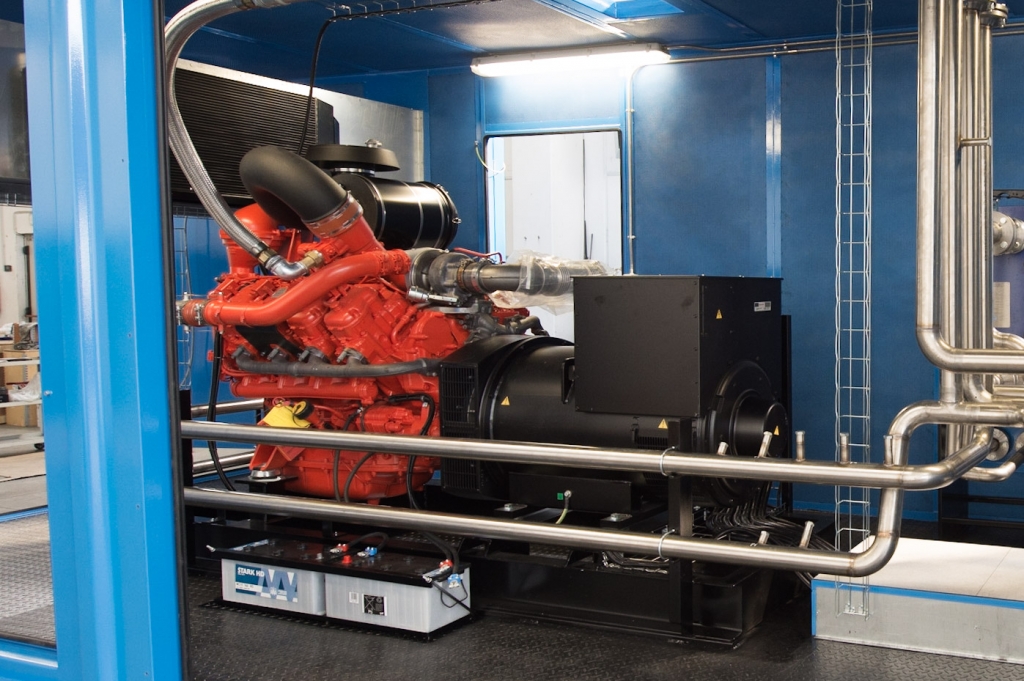

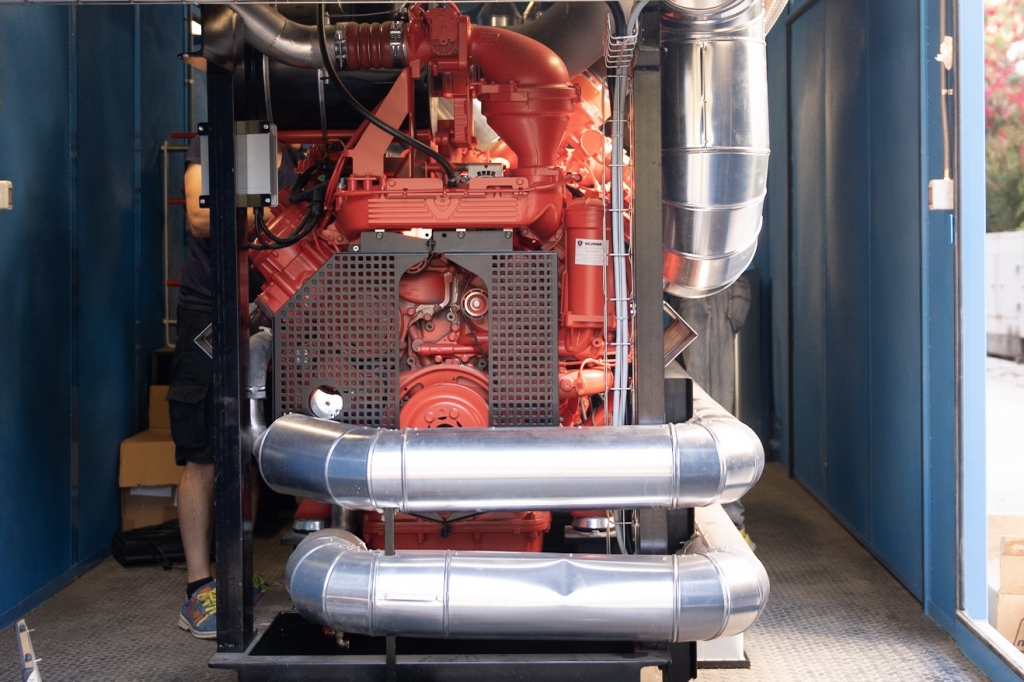

The first gas cogenerator with a Scania engine, namely 16 liters and 330 kilowatts, powered by natural gas has recently been installed at a tannery in Solofra, in the province of Avellino, in Southern Italy. The goal is to ensure greater economic and environmental sustainability in terms of water heating for all the tannery’s processes. […]

The first gas cogenerator with a Scania engine, namely 16 liters and 330 kilowatts, powered by natural gas has recently been installed at a tannery in Solofra, in the province of Avellino, in Southern Italy. The goal is to ensure greater economic and environmental sustainability in terms of water heating for all the tannery’s processes.

The company in which the cogenerator was installed is the Conceria Ferrante, founded in 1996 at the behest of Graziano Ferrante, which operates within a small cluster with several companies specializing in leather tanning for clothing, footwear and leather goods.

THE 50TH ANNIVERSARY OF THE ‘KING OF THE ROAD’

Energy efficiency and sustainability

Alongside the Conceria Ferrante there was DEF power, a primary company engaged in the market of high-tech gensets, which worked closely with the Italian tannery. An important target for the two players was that of improving the energy efficiency of the tannery itself, with important advantages in terms of both overall efficiency as well as environmental sustainability.

The reasons behind the gas cogenerator with a Scania engine

SCANIA OC16: BIOGAS STEP BY STEP

According to Gianromeo Brugnetti, Sales Manager Industrial Engines Division at Italscania, «the choice of the Scania engine for the cogeneration unit provides the tannery with some important advantages. First of all, such a technology has been completely developed and integrated by Scania. This means that our Italian network takes care of any possible intervention on the engine, without having to turn to more than one interlocutor. Secondly, the Scania engines ensure excellent results in terms of fuel consumption».