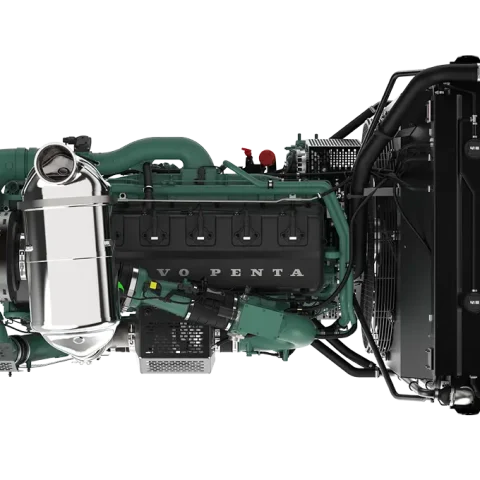

Volvo Penta G17 Natural Gas Engine

Volvo Penta enhances power generation portfolio with G17 natural gas engine

Volvo Penta’s D17 natural gas engine is the next step of the Swedish company in a reliable way to accomplish energy transition.

“The energy transition isn’t one-size-fits-all,” says Kristian Vekas, Product Manager for Industrial Power Generation at Volvo Penta. “It requires multiple technologies and fuel pathways working in parallel. The G17 expands our power generation portfolio with a gas option engineered to meet rising global demand for dependable, lower-emission solutions that are backed by the strength of the Volvo Group and our global support network. It reflects our commitment to providing customers with fit-for-purpose solutions to support their energy objectives as the landscape continues to evolve.”

From the D17 engine block Volvo Penta developed the G17. When methane is more than an alternative

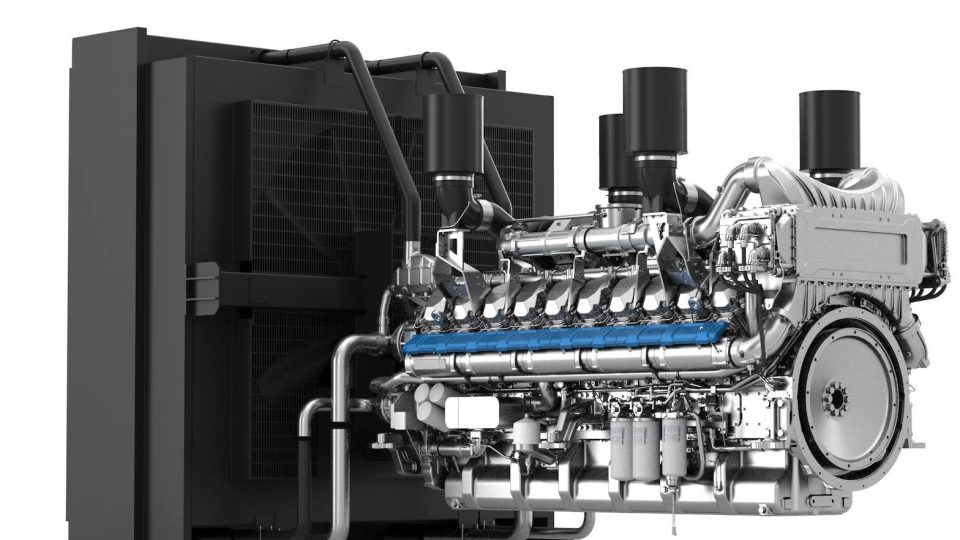

Built on the same platform as the D17 engine, the G17, a 17-liter, 6-cylinder, spark-ignited model, operates on both pipeline-quality, conventional natural gas and renewable natural gas, offering a power alternative that can support customers in reducing their carbon footprint today while maintaining the performance, uptime and reliability they depend on.

The G17’s ability to run using both pipeline-quality natural gas and renewable natural gas provides customers with a lower-carbon alternative to diesel in applications where uptime, environmental performance and operational resilience are critical.

“The G17 is engineered to deliver lower emissions without trade-offs,” says Kristian. “Its flexible fuel capability helps reduce carbon intensity while maintaining the power density, responsiveness and durability customers expect from Volvo Penta’s heavy-duty platform.”

Providing 450 kWe @ 1800 rpm

Engineered to deliver approximately 450 kWe at 1800 rpm, according to the company the G17 offers high power output from a compact footprint. With a smaller enclosure, customers have the capability to reduce installation space and housing material costs, while optimized load acceptance and fast power delivery help ensure dependable performance during demand spikes or grid transitions.

Advanced combustion controls, low-pressure EGR, high-efficiency three-way catalyst and compliance with U.S. EPA stationary power application standards make it a relevant option for companies with strong ESG commitments or strict air quality zones.

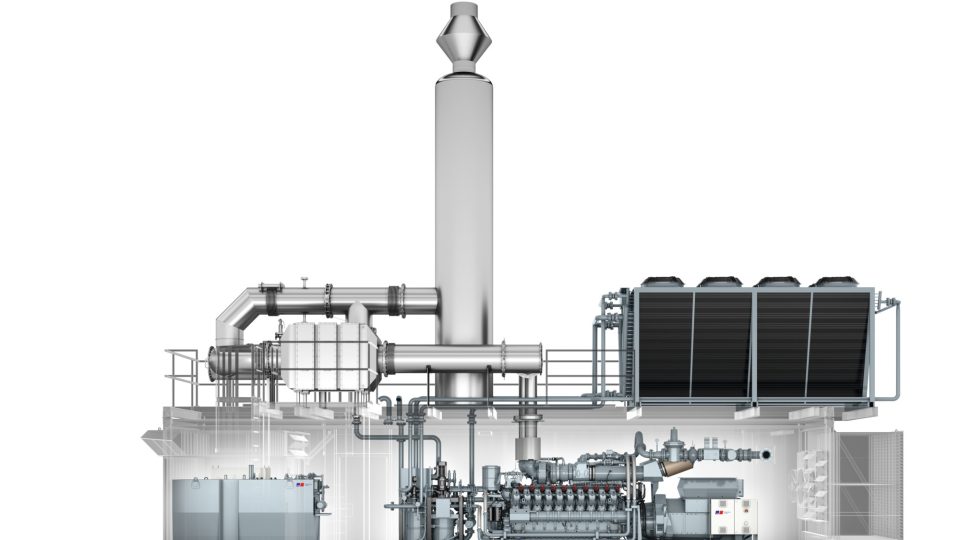

The natural gas engine can also be integrated into broader energy strategies that combine internal combustion engines with renewable fuels and battery systems for energy storage. This modular, scalable architecture enables operators to build flexible power systems that can evolve with changing demand.

With a footprint and cooling system equivalent to the D16 and D17, the engine simplifies installation and retrofit opportunities and is delivered as a fully integrated OEM solution. A streamlined component layout and fewer cylinders improve serviceability and can contribute to reduced total cost of ownership over the engine’s lifecycle.

Volvo Penta is showcasing the G17 natural gas engine at PowerGen in San Antonio on January 20-22 at the Henry B. Gonzalez Convention Center.