Chalmers University of Technology at the World Economic Forum in Davos

Chalmers University of Technology is going to share its battery expertise during World Economic Forum in Davos

Chalmers University of Technology will participate in the upcoming World Economic Forum in Davos, taking place from January 19 to 23. The university will provide its scientific contribution on the hottest technological topic of the moment: batteries.

Chalmers and the battery breakthrough in Davos

During the World Economic Forum in Davos, Chalmers University of Technology, based in Sweden, participates in Science House – an international meeting place for science, innovation and sustainable development.

What’s the porpuse of this initiative? The Swedish University invites journalists to find out about the latest advanced of the world’s strongest battery, and to interview the researcher who thinks that technologies such as AI isn’t “stealing” human jobs – but something we need to address Europe’s imminent skill shortage.

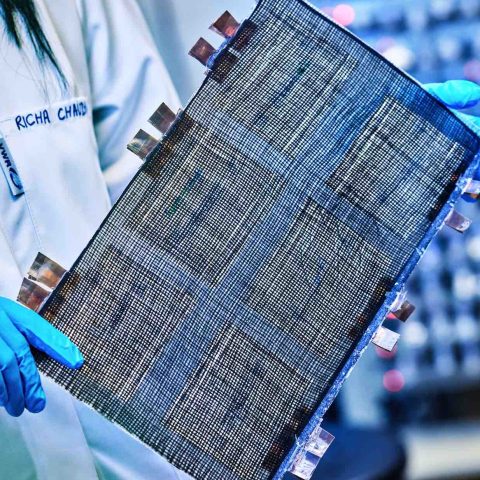

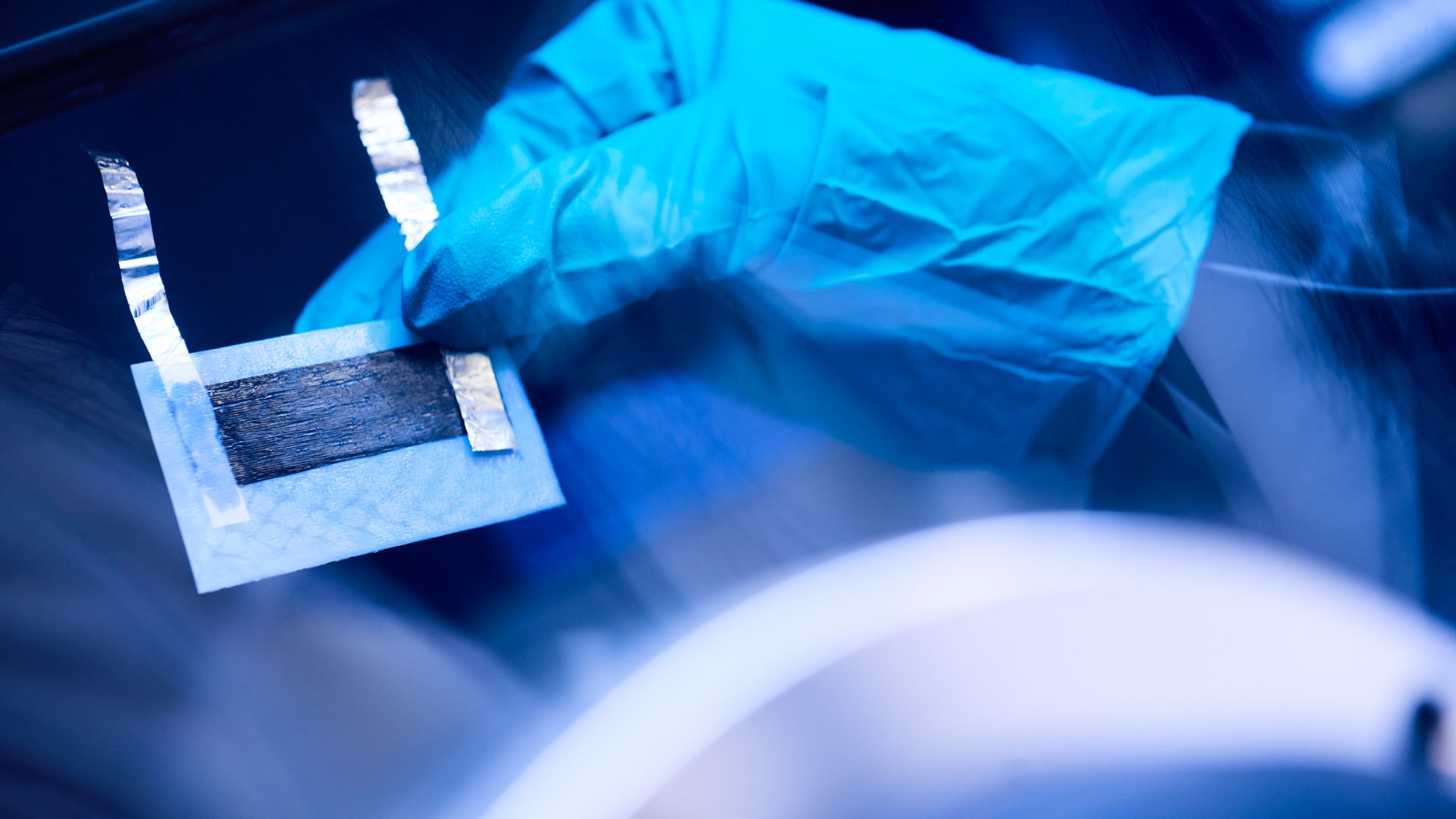

Structural batteries

Structural batteries are materials that, in addition to storing energy, can carry mechanical loads. In this way, the battery material can become part of the structure of a product, offering significant mass savings which means that much lower weight can be achieved on, for example, drones, handheld tools, laptops and mobile phones, and in the long term potentially even for electric cars and aircraft.

When the latest advances were published in September 2024 in the scientific article Unveiling the Multifunctional Carbon Fibre Structural Battery they yielded massive publicity around the world.

The researchers behind the technology have now achieved a new breakthrough in the performance of this innovative material. Yet unpublished results demonstrate structural battery cells with extraordinary multifunctional performance – approaching those of conventional lithium-ion batteries and structural materials such as aluminium and titanium, but in a single composite material. This means that the material is now reaching the point where it becomes truly interesting for industry applications and investments.

When meeting with journalists at Science House in Davos, Professor Leif Asp and Assistant Professor Johanna Xu, Chalmers University of Technology, will be able to talk about their latest breakthrough in greater detail.

Prof. Leif Asp, Chalmers University of Technology, and Prof. Emile S. Greenhalgh, Imperial College London, will be participating in an impact session presenting the structural batteries on Tuesday Jan 20 at 11.30-12:15 at the Impact Hub in Science House, Davos.

Chalmers University of Technology and Imperial College London will also be sharing an exhibition area at Science House, where they will demonstrate examples providing proof-of-concept of the innovative material.

How the technology works

The material is based on a composite material and has carbon fibre as both the positive and negative electrodes – where the fibres in the positive electrode are coated with lithium iron phosphate. The carbon fibre used in the electrode material is multifunctional. In the anode it acts as reinforcement, as well as an electrical collector and active material.

In the cathode it acts as a reinforcement, current collector, and as a scaffolding for the lithium iron phosphate to build on. Since the carbon fibre is electrically conductive, the need for current collectors made of copper or aluminium (for example), is reduced, which reduces the overall weight even further.

“This technology could make electric vehicles lighter and more efficient and could also be applied to aircraft, as potential applications include fuselages.

SBCs are yet to achieve widespread adoption for a number of reasons, but if safety regulations and standards can be developed to support widespread use, they could have a significant impact environmentally and economically.”

About AI stealing human jobs

An ageing workforce along with a rapid shift to digital and green technologies puts pressure on skills development for all generations. Björn Johansson, Professor in sustainable production at Chalmers University of Technology, argues that new technology isn’t “stealing” jobs – the demographic shift means that we need new technology to help us address skill shortage.

At Science House in Davos, Prof. Björn Johansson is available for interviews on how technologies can enable rapid upskilling and make training efficient. Interesting angles might be:

- How AR/VR/XR can augment peoples’ perception, increase learning efficiency and knowledge retention, while bridging skill gaps in a broad range of work situations.

- How AI, machine learning, and language models can be used for upskilling and reskilling to solve tasks and gain insights on products, processes and situations.

- How wearable augmentation technologies such as smartwatches, smartglasses, and smartphones can be game changers for industrial competitiveness. How do we harness the potential of rapid training and upskilling tools?

In Chalmers University of Technology’s demo area in Science House visitors can experience how AI and virtual reality create new possibilities for the production industry:

- By using AI to create a digital twin of production environments, humans can – almost literally – step into the screen. As a digital version of a human interacts within the digital 3D copy of a production system, safe ways of solving problems and finding improvements are possible. Visitors can give the technology a try in the demo area.

- How quickly can you learn how to put a car together? Visitors can put on augmented reality glasses and receive real-time instructions while doing job. The technology minimises the time needed to learn, as well as the need for training and manuals, and is already used to build Volvo trucks at the company’s production facility in Ghent.

As an expert of industrial production, Professor Björn Johansson is also the leader of the MAXBATT Competence Center, wich aims to strengthen Sweden’s competitiveness in battery production. Prof. Johansson can talk about the requirements and challenges for a European battery industry, sharing his profound knowledge ranging from scaling up the technology and ensuring a qualified workforce for future battery factories.