Cummins and Taylor think green with hydrogen engines

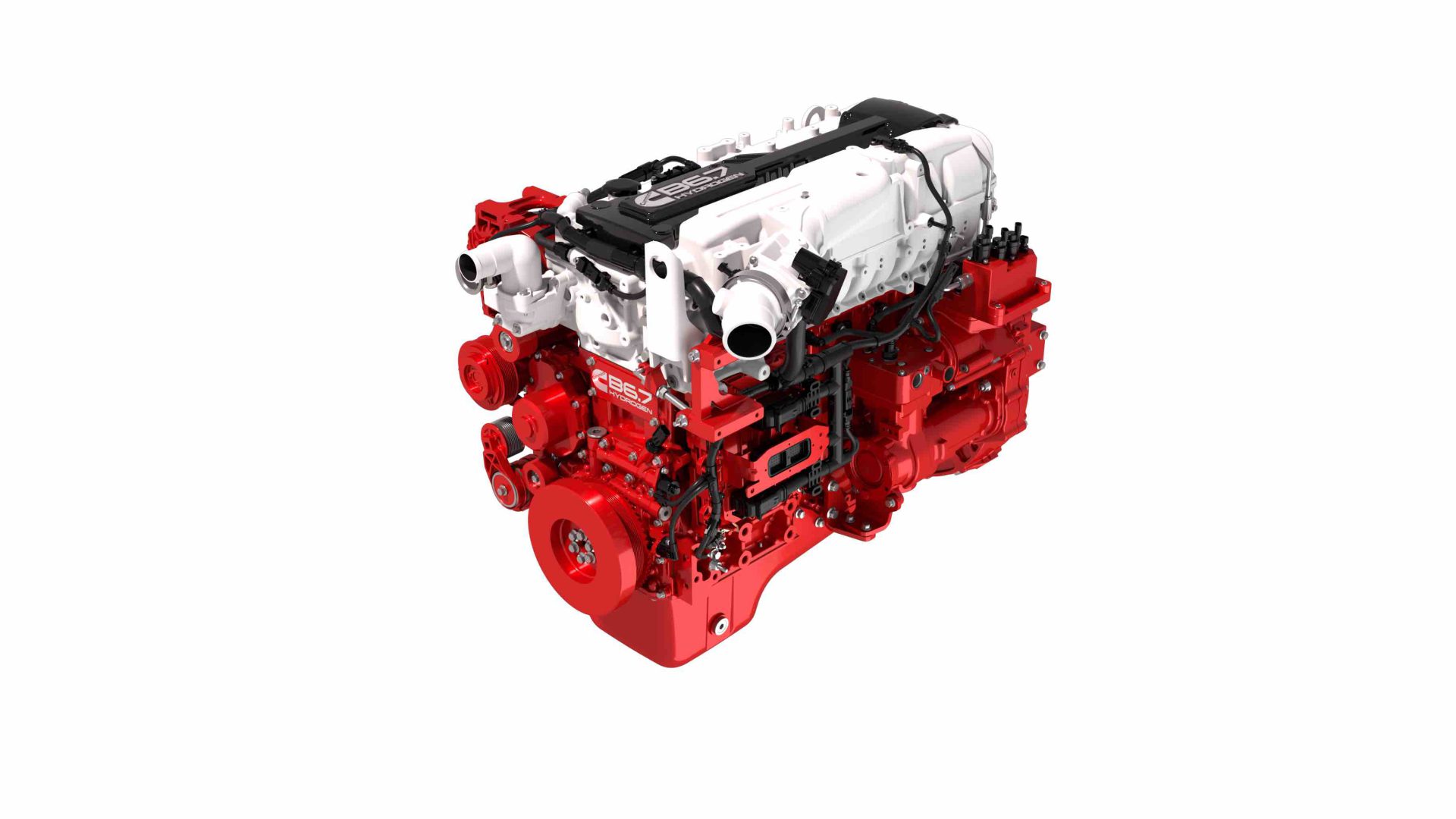

To decarbonise its machines, Taylor chose Cummins ' 6.7 and 15-litre hydrogen engines

Cummins’ commitment to hydrogen has found a major partner in Taylor. After the acquisition of Hydrogenics in 2019, the first tests with Alstom on the hydrogen train, and the agnostic engine, the time has come to tackle off-highway applications for the 6.7- and 15-litre hydrogen engines.

For Taylor there are the 6.7 and 15 litre hydrogen-powered Cummins

Cummins and Taylor Machine Works a leading American manufacturer of heavy industrial lift equipment, announced a signed letter of intent with plans to integrate the Cummins 6.7-liter and 15-liter hydrogen engines into the Taylor product line. This collaboration will help realize the decarbonization goals of industrial steel, wood products, concrete, oil and gas, and port operations markets. Taylor provides material handling equipment from 1,814 kg to 56,670 kg (from 4,000 lbs. to 125,000 lbs.) lift capacity to industries such as forest products, steel aluminum, ports, stevedoring, intermodal, inland waterways, concrete and precast, oil and gas, as well as warehousing and distribution. For 96 years, Taylor has been committed to meeting the material handling needs of their global industrial customer base, while focusing on its own generational workforce and surrounding communities. Cummins engines power a large portion of more than 100 different models of Lift Trucks manufactured by Taylor for the heavy lift industry.

Taylor involves also ICE

Taylor, along with our valued industrial partners, has undertaken the challenge of manufacturing lift equipment that will not only serve heavy material handling needs, but also bring positive change to neighboring communities. “Beyond Clean Lifting,” our commitment to the sustainable future, highlights Taylor Machine Work’s efforts to develop low and zero-carbon solutions across the entire product line. This effort includes Battery Electric trucks, hydrogen fuel cell trucks, and now Hydrogen Internal Combustion Engines (H2ICE).

Matt Hillyer, Taylor Director of Engineering, stated, ” We are excited to announce our collaboration with Cummins to integrate hydrogen internal combustion engines into Taylor products. This partnership signifies our commitment to a sustainable future, enabling us to offer reliable, cost-effective, zero-carbon solutions for heavy industrial lift equipment, reducing carbon emissions without compromising productivity.“

Hydrogen combustion engines will create a zero-carbon fueled solution that provides cost effective equipment for high load factor, high utilization applications. Key benefits of using this technology include enabling a more-timely solution to reduce carbon emissions without sacrificing productivity. Adding H2ICE to the mix of zero carbon solutions will also reduce the load required from already stressed utility grids. Finally, commonalities with traditional internal combustion equipment will provide solutions that are dependable, as well as easy to service and maintain.

Antonio Leitao, Cummins Vice President Off- Highway Engine Business, said of the plans, “Cummins is pleased to be working with Taylor Machine Works on hydrogen solutions for their equipment. We see hydrogen internal combustion engines as a solution to help drive sustainability improvements in our industry. Hydrogen power will help both OEMs and end-users looking to making carbon emissions reductions on their paths to zero.”