Comparison: 30L yacht engines

The trio is made up of Caterpillar, MAN and mtu and for about ten years it has been raising the bar, with increases of 100 horsepower or so. Read the full comparison in the January issue of Powertrain International.

If this was a Netflix serial, it would probably be Game of Thrones. Without the low blows, intrigues and fantasy atmospheres, Game of Thrones corresponds to what the American sociologist Talcott Parsons would call “need for achievement”. In summary, it is the crystal-clear expression of the three-way competition that has been unleashed in the 2,000-seahorse sector.

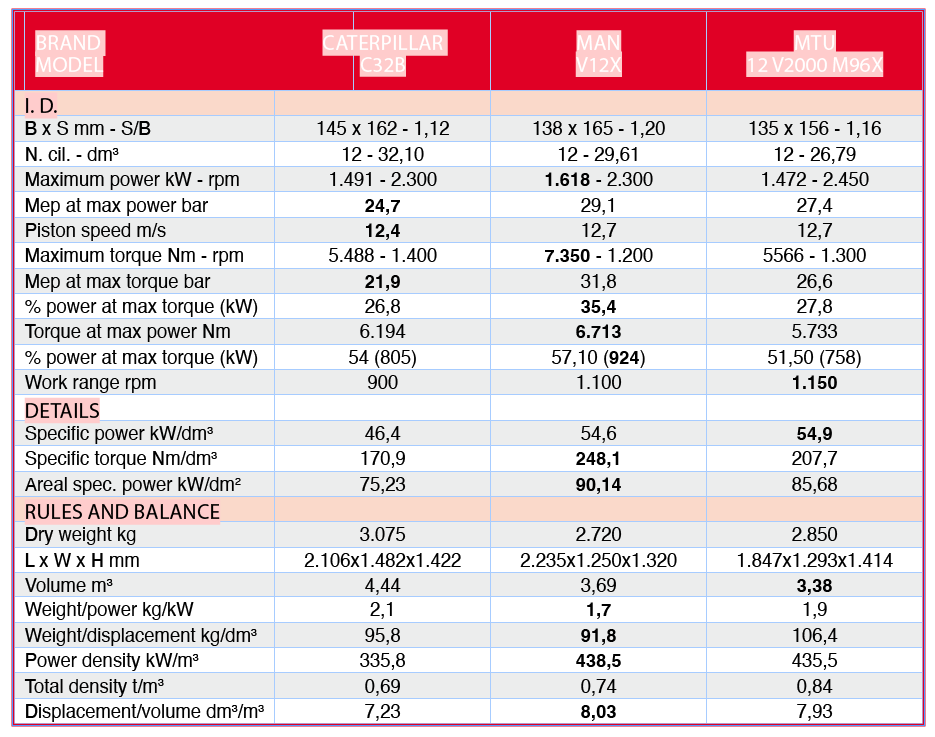

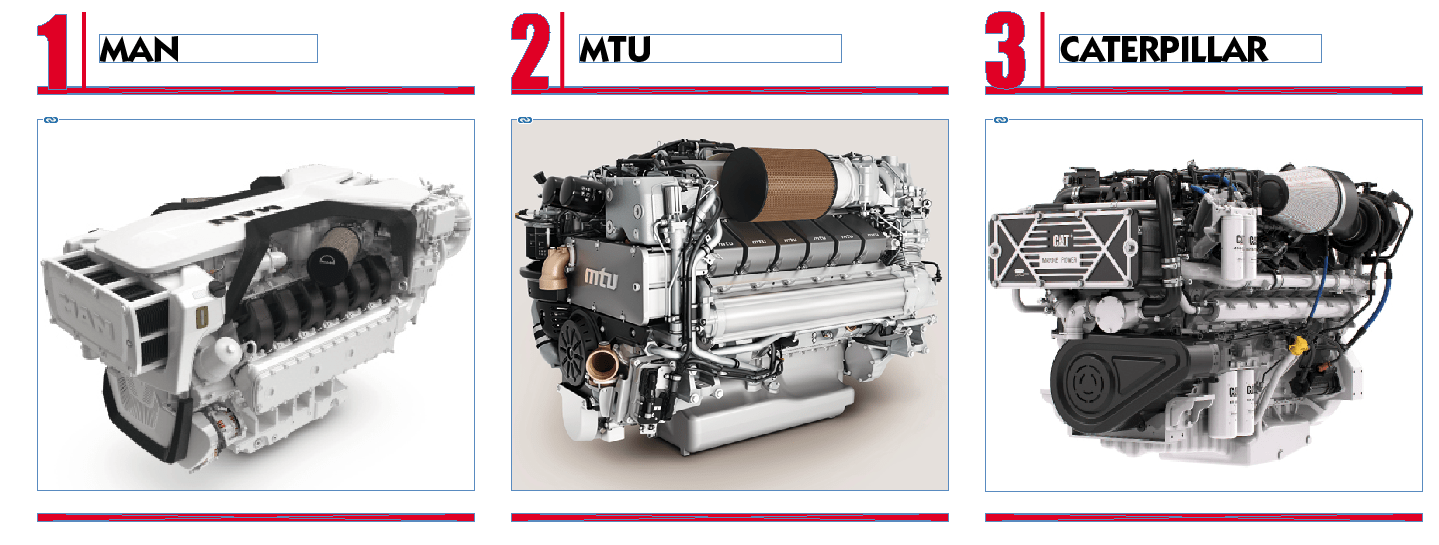

The trio is made up of Caterpillar, MAN and mtu and for about ten years it has been raising the bar, with increases of 100 horsepower or so. It all began in Friedrichshafen, indeed in Cannes, where mtu, in 2014, decided to enter forcefully with the V2000 M96, segmented with 10, 12 and 16 cylinders. A concentration of technological “delicatessens”, such as the triple sequential turbo, the doubling of cooling stages (inter- and after-cooler) and of air filtration and the restyling of Bosch common rail nozzles and of the injection pump by L’Orange.

MAN did not resign itself to the muscular test of its compatriots and raised the power bar from 1,800 to 1,900 horsepower and subsequently to 2,000, focusing on top-of-the-range performance. And Caterpillar? The Americans relaunched two years ago, in the Covid-19 period, with a re-engineering, applied to the C32, capable of whipping the 2,000 horses up to 8 percent of navigation time. The power density reaches unexplored peaks due to the control logic of the ADEM 6 ECM control unit and the timing of injection cycle.

But it doesn’t stop there, because, as we anticipated in the report from Cannes and in the incipit of this comparison, MAN has decided to shift up a gear and completely redesign the barrel. The bore widens by 10 millimeters, going from 128 to 138 millimeters; travel increases from 157 to 165 millimeters. It is therefore a question of joining the legendary 2-litre barrel, one of the archetypes of the motor industry and Nuremberg’s standard-bearer among heavy-duty marine and industrial applications. In terms of cubic volume, MAN therefore slips into a middle position, approaching the 32 liters of Cat.

The picture that emerges from the prospectus is unequivocally rewarding for the sea lion. Separate exception for the specific power, which confirms the primacy of mtu, albeit by very few decimals. It is a completely different story when the two curves intertwine at 1,200 rpm (the lowest start-up revs among these three) and you notice the approximately 1,800 Newtonmeter difference. Assuming an approximate average of 5,550 Nm for Cat and mtu, the difference amounts to 25 percent. Even the specific torque excels, with a gap. It is significantly higher with the C32 than with the V2000 M96X. Also not to be underestimated are the efforts to limit the overhangs, especially in height, and the bare weight, which allow the V12X to look down on its competitors both in terms of dimensions and mass/power ratio. The values expressed by the indices are all in favor of the 2.47-liter barrel. Last but not least, the Diesel Index. Let’s focus on the “best in class”. That “X” at the end of the acronym winks at “next generation”, while the intuitive indications of the architecture remain unchanged: 12 V-cylinder.

“MAN engines are synonymous with sturdiness. That is why numerous measures have been taken for the MAN V12X as well to ensure this high standard of durability and reliability, but also of future safety”, explains Werner Kübler, Head of Engineering at MAN Engines.

Among other things, as the Bavarian manufacturer scrupulously reports, thickness of the crankcase walls has been increased in significant places, the bolt connection between the upper and lower crankcase sections has been optimized and a new crankshaft has been installed with larger diameter bearings. Great attention is also paid to the results of numerous test bench tests with associated long operating times and to the experience gained with customer water tests. In addition, the results of the E3872 stationary gas engine developed in parallel complement its development. The counterpart for power and heat generation is based on the same basic engine and was presented for the first time at the end of 2021. This generation X of pleasure engines has taken precautions against stresses that could potentially lead to wear.

This calibration of the MAN V12X was therefore designed for a full load ratio of up to 20 percent. The new coolant pump and thermostat housing ensure adequate coolant supply for long engine life. The engine is also available with an optional external cooling system, as an alternative to the closed coolant circuit. The revamped cylinder head of the V12X, also significantly optimized in terms of flow and cooling, was designed to achieve the same development goal. Furthermore, the oil supply has also been modified by completely renovating the circuit, with pumps and oil coolers, as well as optimizing the flow. In the V12X MAN Engines has drawn for the first time on a marine engine on a device in vogue for industrial applications, the hydraulic valve clearance adjustment. This eliminates the need to check and adjust the valve clearance and protects the tappets. Clearly the common rail played a key role in terms of performance, with an injection pressure of 2,200 bar, in concert with the renewed engine control unit. The after-treatment of the exhaust gasses makes it possible to meet the IMO Tier III requirements. The modular system, EGA in the MAN taxonomy, allows for different installation possibilities, as the individual components of the SCR catalyst can be positioned differently, enabling flexible system integration.

The V12X is also available in combination with the proprietary hybrid system, also presented at Cannes last year, the “MAN Smart Hybrid Experience”. “In the first stage, we use existing solutions such as dual fuel hydrogen technologies or regenerative diesel to reduce CO2 emissions. Our hybrid system, the ‘MAN Smart Hybrid Experience’, offers an entry point into the electrification of marine drives, also for the MAN V12X. For the future, we will continue to draw on the group experience and further develop suitable solutions for our customers,” says Mikael Lindner, Head of MAN Engines. The 1,618-kilowatt V12X-2200 will be available from mid-2024.

TO READ THE FULL ARTICLE IN THE JANUARY ISSUE OF THE MAGAZINE, CLICK HERE