MAN Engines and alternative fuels: a sustainable paradigm

“Our goal is to transform our portfolio so that we offer our customers solutions in AG and CE technology, for watercraft and in PG that do not release CO2 locally. Our ambition is to use our products and services to simplify the business of large and small OEMs towards decarbonisation,” says Mikael Lindner, Head of MAN Engines. Read the full article in the November issue.

MAN Engines has all the tools to apply its paradigm to the energy transition. Where the Diesel cycle engine was born, methane gas fuelling for stationary applications was pioneered. When talking about biogas CHP in the background, one can’t ignore the roar of the Lion. MAN is intimately multitasking, targeting marine, PG and off-highway applications, with R&D support for truck&bus, as imprinted in its name.

Electrification is the way to go: let us mention the eTruck, as an example. According to MAN Truck & Bus there are more than 500 order requests for the electric Lion suitable for long-distance transport. In mid-September, the 1000th MAN Lion’s City E rolled off the production line at the MAN plant in Starachowice, Poland. “MAN is accelerating its transformation and taking big steps towards emission-free drives. The focus at MAN Truck & Bus and the Traton Group is clearly on battery-electric drives,” says Alexander Vlaskamp, Chairman of the Executive Board of MAN Truck & Bus SE. “Recently, however, we have also stepped up our R&D efforts in the hydrogen sector and built a truck prototype with a hydrogen-based combustion engine for future niche applications and for off-road propulsion, for example, or at sea,” says Vlaskamp. For the batteries of the electric vehicles, almost 100 million euros will be invested in this important future technology at the MAN plant in Nuremberg, among other places.

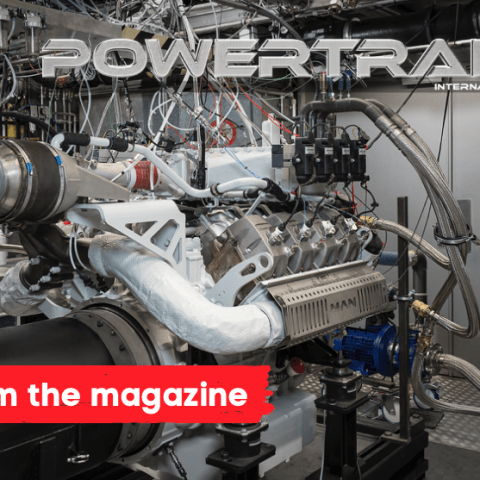

In the medium and long term, diesel and gas engines will not only be pure battery packs, but also the appropriate software in addition to the hardware. Proving its strong commitment to ICE, MAN invests in its hydrogen interpretation. Such Vlaskamp anticipated, a truck prototype has therefore already been equipped with a hydrogen combustion engine. It has been in testing since the end of 2021. At the heart of the demo truck is a 16.8L hydrogen engine with approximately 500 hp and 2500 Nm based on the diesel engine kit. For the off-road sector, MAN Engines presented the prototype of a possible hydrogen combustion engine for the snow groomer PistenBully 800 from Kässbohrer.

MAN Engines has been testing also a H3268 stationary combustion engine (BxS 132×157 mm) powered by hydrogen on the test bench since the beginning of May 2023. Since mid-2021, stationary gas engines of the MAN E3262 LE202 (turbocharged lean-burn engine) and MAN E3262 E302 (naturally aspirated lambda-1) types have been designed by MAN Engines for the admixture of up to 20% hydrogen (H2) by volume when operated with natural gas. With an admixture of 20% hydrogen by volume, the Lambda-1 engine E3262 E302 achieves CO2 savings of 5.7% and an HC reduction of 23.0%. The turbocharged lean-burn engine E3262 LE202 achieves CO2 savings of 11.2% and a HC reduction of 17.4%. In addition, an increase in efficiency of 1.2% means that a particular efficiency metric or parameter has really improved by 1.2%.

In June 2022, MAN Engines had already approved all marine engines from its current product portfolio for use with regenerative diesel in accordance with the EN15940 standard in Europe and the US specification ASTM D975 of the American Society for Testing and Materials (ASTM). All engines from the off-road sector (agricultural machinery, railway, construction and industrial applications) recently followed in May 2023. The combustion of renewable diesel emits approximately 30% less particulate matter and roughly 10% less nitrogen oxides. Moving “into the water”, the partnership with CMB.Tech generated the first hydrogen dual-fuel engine. The MAN Smart Hybrid Experience was presented for the first time in 2021 for yacht applications.

SE VUOI LEGGERE L’ARTICOLO COMPLETO, CLICCA QUI OPPURE SCARICA IL PDF