MAN D3876 engine equips snow groomer PistenBully 800

MAN Engines is now equipping the PistenBully 800 from Kässbohrer Geländefahrzeug with its MAN D3876 engine. The basis for the delivery of the in-line six-cylinder engine was the further development and adaptation of the MAN D3876 to the extreme working environment of the new high-performance snow groomer from Laupheim.

MAN Engines is now equipping the PistenBully 800 from Kässbohrer Geländefahrzeug with its MAN D3876 engine. The basis for the delivery of the in-line six-cylinder engine was the further development and adaptation of the MAN D3876 to the extreme working environment of the new high-performance snow groomer from Laupheim.

“We have also modified our high-performance MAN D3876 for the PistenBully 800 for cold-start capability, use up to 2,500 metres in altitude without power reduction and extreme lean angles,” says Werner Kübler, Head of Engineering MAN Engines.

Michael Kuhn, Head of Development at Kässbohrer Geländefahrzeug, is very satisfied with the result of the cooperation: “Our PistenBully 800 sets new standards in slope preparation. The MAN D3876 and the MAN Engines development team have made an important contribution to this.”

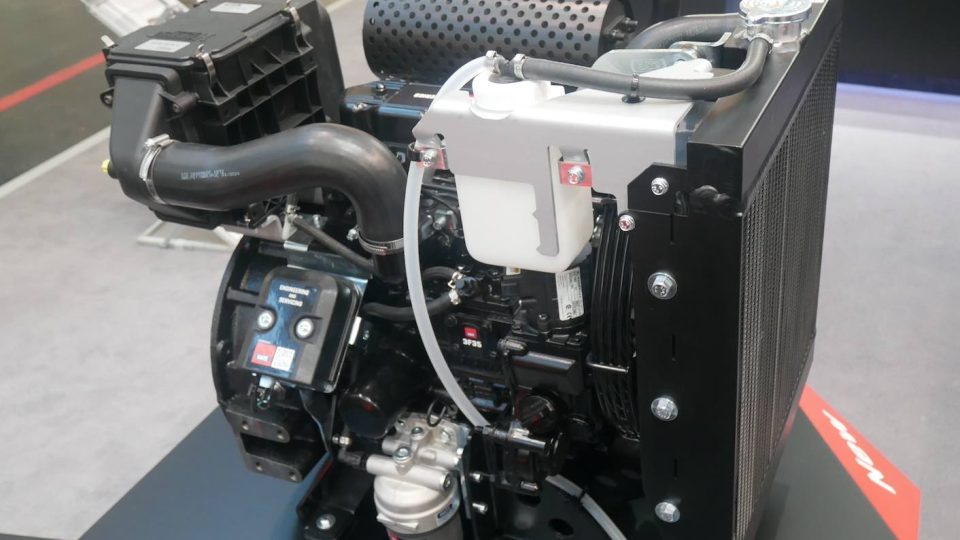

In addition to the MAN D4276 on the same platform, the MAN D3876 is the most powerful in-line six-cylinder engine in the portfolio of engine manufacturer MAN Engines. With a displacement of 15.3 litres, the engine in the PistenBully 800 offers a whopping 2,900 Nm of torque and 612 hp (450 kW). As a result, the currently most powerful PistenBully in the series portfolio achieves a unique thrust for the preparation of slopes. One of the decisive factors for this performance is the VTG turbocharger, which optimizes the dynamic response in the off-road-specific speed ranges thanks to its variable turbine geometry (VTG). In addition, this technology displays the maximum power and torque over a wide speed range. Especially on steep slopes and in changeable terrain, this means a constant thrust performance.

In order to ensure the cold-start behavior even at temperatures as low as -30° Celsius, the combustion behavior was also modified when starting the engine. For work at high altitudes, on the other hand, the MAN engineers had to redesign the behavior of the charge air components to the thinner air at high altitudes. In addition, the specialists for off-road engines from MAN Engines optimized the oil pan and oil pump of the MAN D3876. In contrast to the on-road version, this allows lean angles of up to 45° on all sides. “Our MAN D3876 is precisely tailored to the PistenBully 800 and its requirements. At MAN Engines, we benefit from decades of application-specific engine development for a wide range of applications as well as the large-scale production experience of our parent company MAN Truck & Bus,” says Head of Development Kübler.

All D3876 engines are equipped with a common rail injection system that operates at an injection pressure of 2,500 bar. This makes the system one of the systems with the highest pressures on the market and guarantees optimum fuel atomization quality. As a result, significant savings in fuel consumption can be achieved. “Our development goal has always been to achieve the best fuel consumption. This saves the operator costs and also reduces the CO2 emissions of the engines,” says Head of Development Kübler. Specifically, the MAN D3876 in the PistenBully 800 offers one third more thrust than all snow groomers currently available on the market. At the same time, it saves up to 9% fuel per cubic meter of shifted snow and emits correspondingly less CO2.

Equipped with the latest exhaust technologies, the MAN D3876 complies with the current and strict EU Stage V emission regulations. In addition, the engine is approved for operation with HVO (hydrogenated vegetable oil), also known as regenerative diesel – according to the EN15940 standard. Customers can use it to replace conventional diesel fuel – or even mix it. For Werner Kübler, Head of Engineering at MAN Engines, there are also other clear advantages: “There are no performance losses or disadvantages with regard to the service and maintenance intervals of our MAN engines, and the exhaust gas aftertreatment system also works without any problems.” Above all, however, regenerative diesel ensures clean combustion with up to 90% less greenhouse gas emissions (CO2) in the exhaust gas compared to conventional diesel.

MAN Engines: ready to integrate hydrogen

In order to be able to completely dispense with CO2 emissions in the exhaust gas in the future, MAN Engines already has concepts for a pure hydrogen combustion engine for off-road applications. This – called MAN H4576 – is based on the basic engine of the MAN D3876 and uses the same installation dimensions, so that it can replace the diesel engine in the PistenBully 800 in due course. “We are well prepared to integrate hydrogen combustion engines into off-road applications. When the market is ready, MAN Engines will offer the right solutions,” says Mikael Lindner, Head of MAN Engines.An exhibit of the MAN H4576 will be on display at the Interalpin trade fair in Innsbruck from April 19 to 21 at booth A28 of Kässbohrer Geländefahrzeug.