Volvo Penta. The marine sector towards hybridization

Volvo Penta, the marine sector follows the automotive The marine industry, especially when it comes to professional applications, is among the most involved in the process of hybridization of the transmission. Even more, after hybridization has crossed the confines of the automotive industry. Moreover, the marine sector is the one that keeps the most effective […]

Volvo Penta, the marine sector follows the automotive

The marine industry, especially when it comes to professional applications, is among the most involved in the process of hybridization of the transmission. Even more, after hybridization has crossed the confines of the automotive industry. Moreover, the marine sector is the one that keeps the most effective relationships with OEMs. In both professional and recreational boating, there are no captive producers. Each site is, in fact, an assembler of components produced by others and the engine is one of them. This makes it easier, then, to integrate the classic diesel with an innovative hybrid powerline.

First stop 2020

Thanks to its leadership, Volvo Penta announces the hybridization of its engines for professional and recreational use combined with the IPS propulsion system, already widely used for its extraordinary versatility. This is a first step, which will take shape with the first prototypes in 2020 and then debut with the final version the following year in the professional world and, later, in the recreational one.

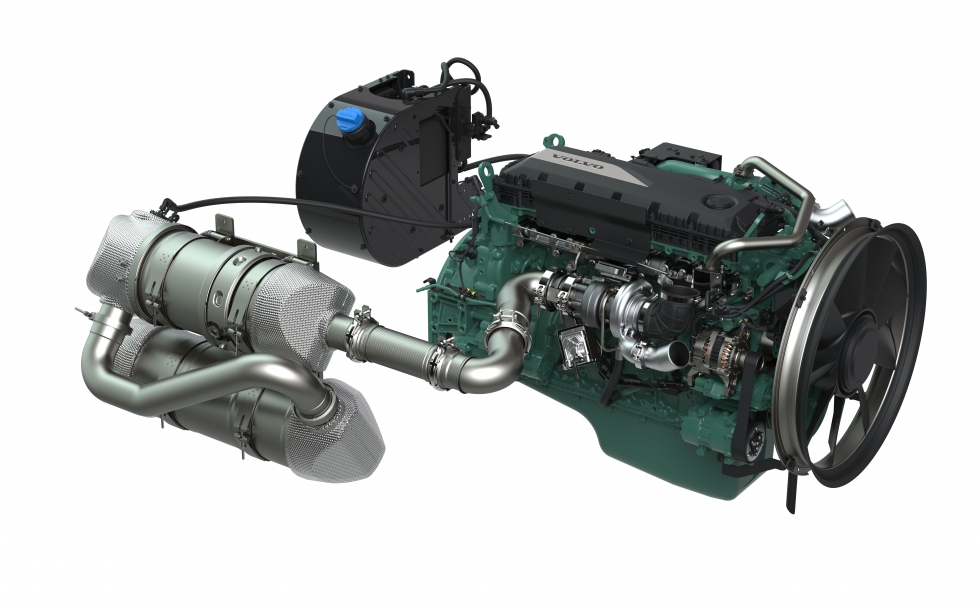

The engines for professional use are all six-cylinder, starting from 7.7 liters of the D8, up to the 10.84 liters of the D11 and to the 12.8 liters of the D13. Common to all the dual-intake turbocharger. In the smaller engine, the common rail injection replaced the high-pressure pump injectors of the larger displacement versions.

The power outputs depend on the calibrations. They range for the two largest engines between 354 and 554 kilowatts to the crankshaft, with a speed between 2,200 and 2,300 rpm. Official figures for the eight liters are missing (currently not available with IPS). However, considering the calibration of the inboard, the eight liters should reach 330 kW in R3 and partially overlap with the minor settings of the D11, even if with a slightly higher regime that starts at 2,700 and goes up to 2,900 rpm.

Hybrid and full-electric

At least three operating modes are possible with the motor keyed immediately after the output of the drive shaft to which a clutch connects it. The first two operate with the clutch engaged, so the engine can add its power to that of the internal combustion engine or work as a generator and recharge the batteries. More interesting, due to the presence of the Volvo Penta IPS, operation with the clutch disengaged.

In this fully-electric mode, you can switch from cruising to maneuvering on the way. Completing the powerline, at least from a functional point of view, the inverter, the battery pack and the Battery management system. The BMS will exploit the experience gained with the Volvo Penta Evc (Electronic vessel control), with which it will interface. In electric mode, the maximum speed should be set at no less than 10 – 12 knots.

As with other hybrids, the presence of the electric motor reduces the operating hours of the diesel (especially at low loads, the most wearing conditions) and can even allow its downsizing. Obviously, you can also recharge the batteries by connecting to the fixed network during moorings, perhaps using electricity from renewable sources even if the appropriate columns will remain utopic for years.