Lubricants for zero emissions

Interact Analysis takes a closer look at lubricants for zero-emission vehicles

Are lubricants manufacturers ready for seismic impact of zero emissions transport? This is the question posed by Alastair Hayfield, Senior Research Director at Interact Analysis. Below is the response from the writer of Interact Analysis himself.

Even in the case of lubricants, zero emissions are not achieved with a magic wand

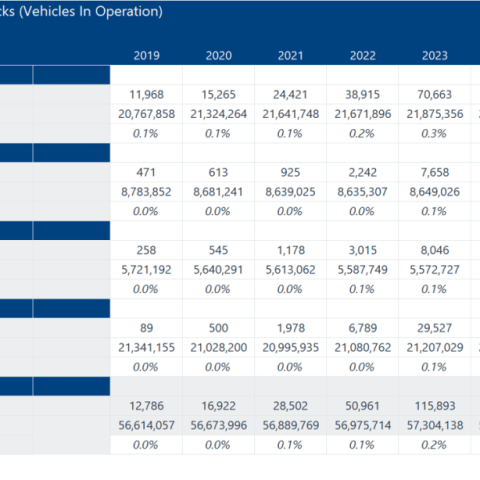

A rapid uptake of battery electric trucks and buses is going to reduce demand for diesel fuel. This has started off slowly, but will accelerate out to 2030, particularly in certain markets. The total number of battery electric trucks in operation will rise to around 1% by 2025. However, by 2030 7% of trucks on the road are forecast to be batter electric. The off-highway market is taking a much longer time to transition towards electrified and new fuel power trains and away from combustion, particularly when it comes to larger machinery. This is partly because of the variations between machines, each often requiring different design and components, whereas most trucks are very similar in terms of design and components. So, if you are in the lubricants industry, you don’t need to switch everything over immediately, but it’s a clear trend towards electrification in particular.

To open new icons on the desk

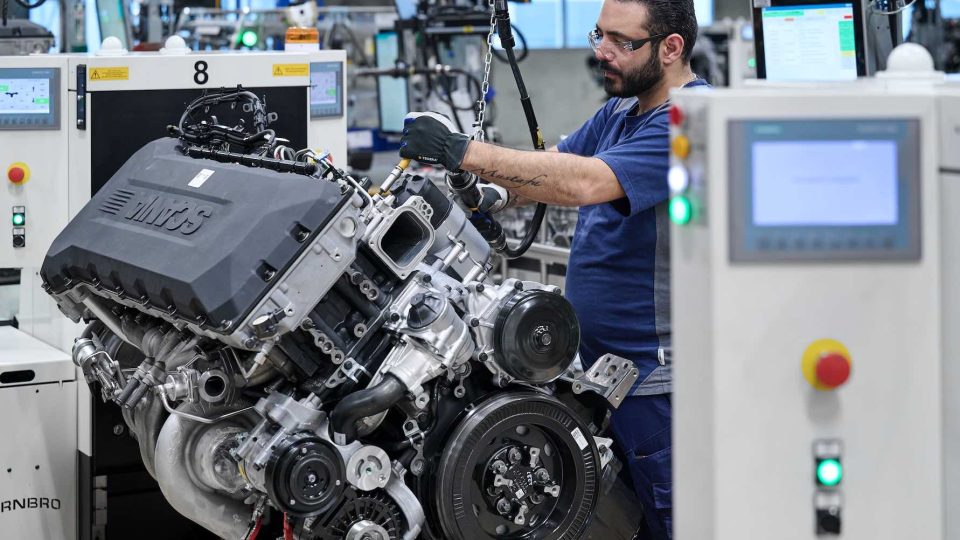

Tailored e-lubricants could provide a potential new market for manufacturers, with products that enhance the performance and longevity of moving parts, with some companies already entering the arena or developing new formulations. With the importance of reducing friction and energy consumption even more important for new fuel vehicles, in order to conserve battery life or reduce time between refueling, there are very real opportunities for those companies that create new formulations for zero emission vehicles. Hydrogen ICE could provide more opportunities, as there is a greater need for lubricants, and the engines are more similar to conventional ICE. However, the market is moving slowly and It should probably come as no surprise that material handling solutions – like forklifts or AWPs – are electrifying fastest. Larger construction equipment could be better suited to hydrogen ICE and more tailored formulations in the longer term as it is not easily powered by BEV technology, and machinery deployed in remote locations cannot be easily recharged. Now is a great time to think about what these new formulations might look like or what gets the best performance out of an electric, hydrogen or biodiesel engine. Keeping an eye on the electrification and new fuel trends and forging partnerships with companies like manufacturers developing new fuel engines now could result in big payoffs in the future.