Mann+Hummel focused on sustainability and innovation

Mann+Hummel presented its innovation for the industrial business What innovation means for Mann+Hummel: clean air, energy and resource efficiency, less operating costs and predictive maintainance through digital components. This is the aim of the new technologies presented by the filtration specialist at the ComVac in Hanover. The focus of the developments in the industrial business […]

Mann+Hummel presented its innovation for the industrial business

What innovation means for Mann+Hummel: clean air, energy and resource efficiency, less operating costs and predictive maintainance through digital components. This is the aim of the new technologies presented by the filtration specialist at the ComVac in Hanover. The focus of the developments in the industrial business is on filtration, systems competence and proximity to customers worldwide.

StarBox series for energy-efficient air/oil separation of compressors

StarBox XT and StarBox 2 are the new spin-on separators for air/oil separation of compressors. Both separators can operate also in compressors with a Variable Speed Drive (VSD).

The StarBox XT is the new standard series. It offers a stable function in different operating ranges as well as less oil consumption by approximately 30 percent. Mann+Hummel has developed a new sealing concept for a secure maintenance. Scratching of sealing surfaces with subsequent leakage or shearing of sealing elements during filter replacement is excluded by the design. The new StarBox XT series can work directly on existing compressors.

StarBox 2 offers decisive advantages in relation to energy consumption. Mann+Hummel developed the spin-on separator series especially for stationary and mobile compressors. Up to a performance of approximately 55 kilowatts. The StarBox 2 separates the oil from the air while managing to reduce the power consumption.

This allows StarBox 2 to maintain a pressure loss up to 25 percent lower. This is possible thanks to an improvement in the flow characteristics in the connection area and a new sealing concept. At the same time they improve the assembly safety.

Mann+Hummel and CMBlu together for sustainable large-scale battery storage

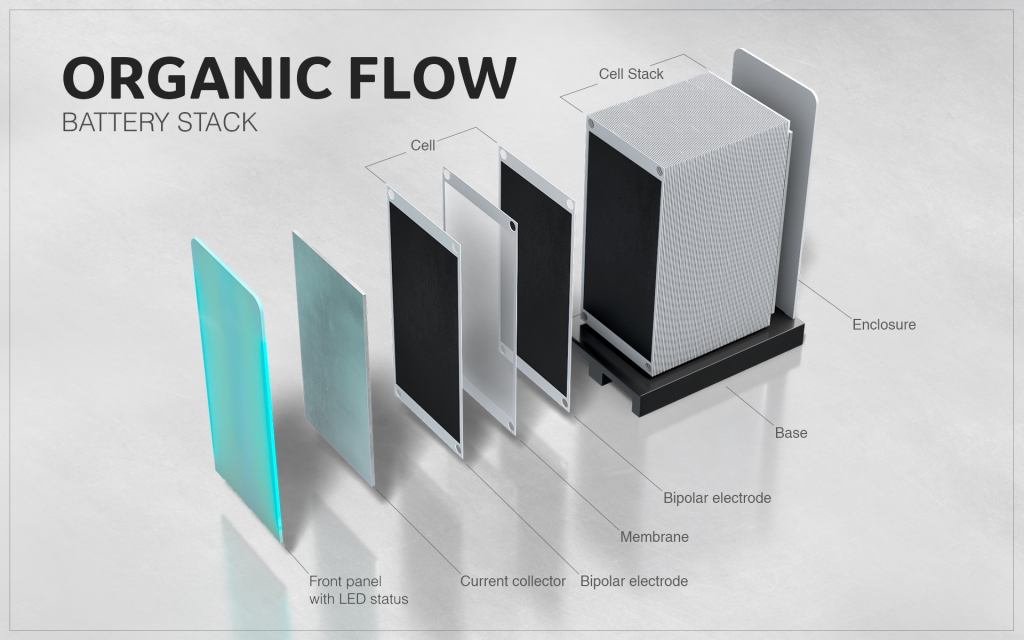

CMBlu Energy and Mann+Hummel signed an agreement for the joint development of energy converters for organic redox flow batteries. The aim of both partners is to support the innovation of electric mobility through charging infrastructures and offer the energy sector a sustainable and highly cost-efficient storage technology for a successful energy transition.

These batteries essentially consist of two tanks of liquid electrolyte and an energy converter. The converter consists of a large number of adjacent rows of cells (battery stack). The liquids are pumped through the battery stacks and it is charged or discharged as required. CMBlu will realize special pilot projects with reference customers in the next two years. Starting in 2021, CMBlu plans to market the first commercial systems.

Benefits of Organic Flow Batteries innovation

Similar to the principle of conventional redox flow batteries, CMBlu’s Organic Flow Batteries store electrical energy in aqueous solutions of organic chemical compounds. These come from lignin that are pumped through the energy converter, i.e. battery stack. The special feature of the flow batteries is, in particular, that the capacity and electrical output can scale independently. The number of stacks defines the output of the batteries. A higher number of stacks multiplies the output. The capacity of the battery depends on the size of the tanks. This, in particular, allows flexible customization to take into account the respective application area. For example, the batteries can store solar power several hours and then feed it into the grid at night.

Different applications in the grid

Organic Flow Batteries are suitable for different application areas in the power grid such as the intermediate storage of power from renewable energy generation. Otherwise, also in connection with the balancing of demand peaks in industrial companies. An additional application area is the charging infrastructure for electric mobility. The batteries enable a buffer storage to relieve power grids which do not need an upgrade for additional loads. It enables simultaneous fast charging of electric vehicles. Moreover, to decentralize the charging network for electric vehicles a high performance and scalable energy storage system is necessary.