Hyster chose MTU engines

Hyster chose MTU engines for Stage V Big Trucks in Europe Jan Willem van den Brand, Director Big Truck Product Strategy & Solutions at Hyster Europe, said: «Our heavy industry and port customers in Europe who will require a Stage V driveline, can continue to expect highly efficient trucks with low fuel and DEF consumption, […]

Hyster chose MTU engines for Stage V Big Trucks in Europe

Jan Willem van den Brand, Director Big Truck Product Strategy & Solutions at Hyster Europe, said: «Our heavy industry and port customers in Europe who will require a Stage V driveline, can continue to expect highly efficient trucks with low fuel and DEF consumption, benefiting from high productivity levels and fast operations with the power available».

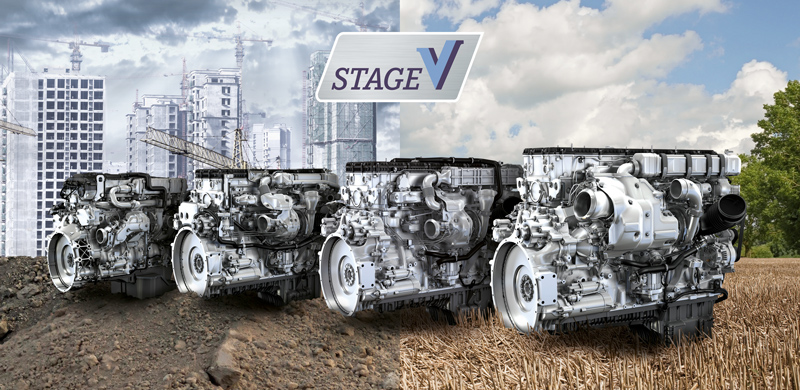

Hyster lift trucks over 8 tonnes, Container Handlers and Reachstackers will be equipped with the Stage V-compliant MTU Series 1000 and 1100 engines. The exact availability varies per series and will be communicated in due course. The engines have been specially designed for industrial applications such as material handling and further developed to meet Stage V regulations. They are based on commercial vehicle engines from Daimler.

Lars Kräft, Vice President Industrial Business at MTU, said: «We are very pleased, that Hyster, one of the leading global brands of materials handling equipment, decided to power its new vehicles with our engines».

MTU RAIL ENGINES FOR CRRC TRAINS

Benefits for the final user

The engines will support the durability of Hyster Big Trucks. They focus on delivering reduced total cost of ownership (TCO), great reliability and high performance in tough, heavy-duty applications.

«These engines have a highly successful track record in both on-road and off-road applications such as forestry or agriculture. They are also particularly suited to intermittent applications like our business serves.» added van den Brand, explaining that the power ratings range from 129kW to 280kW depending on model.

«With the optimal match of engine sizes to the trucks and applications, customers can handle the heaviest of loads all day long, with quick turnaround times. Customers can expect to boost productivity with more power available for faster operations whether it is handling containers in the Swedish winter or steel pipes in the hot Italian summer».

Produced at the Mercedes-Benz plant in Mannheim, Germany, the engines focus on robustness and durability up to high running hours. The engines have been optimised to work well in intermittent duty applications, resulting in lower engine temperatures, less component wear and reduced noise levels.

Sufficient power reserves also result in less stress and parts wear. With also long service intervals of 1000 hours, good access to main service parts and outstanding durability, the engines are expected to help reduce service costs. Furthermore, Hyster Europe will work in close cooperation with MTU to ensure its dealer network will be fully trained and equipped for service support, meaning that end users will receive optimum support throughout their entire product life-cycle.