Volvo Penta highlights road to net-zero at Bauma 2022

Volvo Penta is presenting new technologies and service offerings at Bauma Munich 2022 that will help support both the current demands to reduce emissions as well as the future business needs of industrial customers across a range of applications – including construction and mining.

With the unveiling of its dual-fuel hydrogen engine as well as the new cube battery at its stand, Volvo Penta ’s commitment to sustainable power solutions to meet the industry’s net-zero ambitions is on full display at Bauma Munich. The company is also highlighting how it’s ramping up progress in its services offering, focusing on creating value with customers through connected solutions.

Volvo Penta’s latest power solutions are another step towards helping customers transition to net-zero emissions and achieving the company’s commitment to the Science Based Targets initiative (SBTi), where it aims to reach net-zero value chain emissions by 2040.

Volvo Penta: powerful partnerships

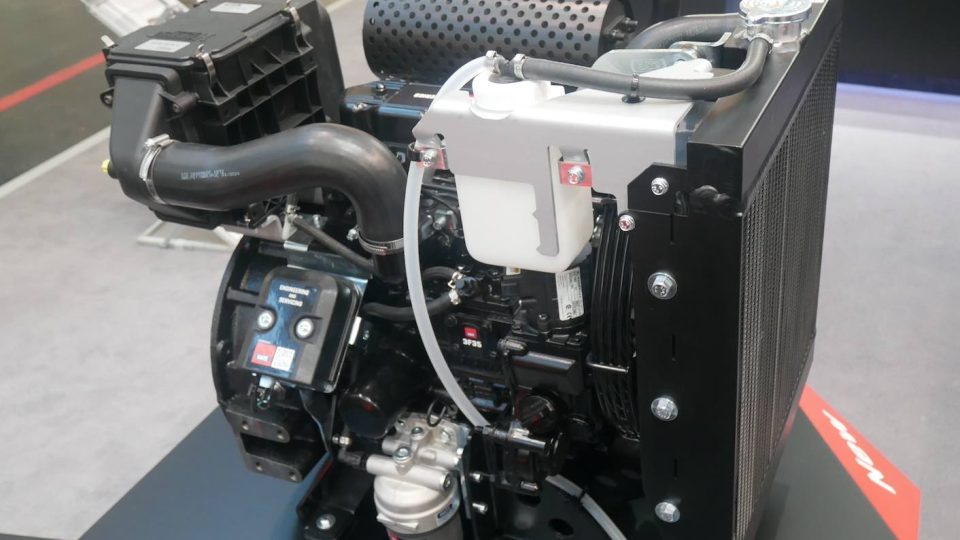

Volvo Penta forms select collaborations and close partnerships as a cornerstone of its business strategy. For example, the integration of the hydrogen system onto Volvo Penta’s D8 engine is part of a partnership with CMB.Tech to establish dual-fuel hydrogen technology as a low-carbon interim solution, before suitable zero-emissions alternatives become viable. This demonstrates Volvo Penta’s strategy to remain competitive with today’s offer, while accelerating new sustainable power solutions. The engine uses hydrogen as a renewable fuel source to reduce CO2 emissions by up to 80%, without impacting power, performance or uptime.

Another aspect of Volvo Penta’s transformation journey is its growing foothold in electromobility as a system supplier. The company is expanding its electric driveline offer with its new cube battery driveline. It is based on proven Volvo Group technology and offers customers increased installation flexibility as well as a 40% increase in energy density. Volvo Penta’s existing electric driveline, which incorporates its flat-pack battery, has also been improved to deliver a 40% increase in energy density. Both these power solutions are backed by connectivity to help customers actively monitor the health of their drivelines in a predictive way throughout their lifespan.

“At Volvo Penta we believe that strong collaboration with customers and partners is crucial to succeed on our transformation journey,” says Anders Konradsson, Vice President of Industrial Sales at Volvo Penta. “We work closely with our customers and form long-term partnerships to create purpose-built power solutions based on their requirements. As part of the Volvo Group, we leverage proven technology, investments and competence from Volvo Trucks, Volvo Buses and Volvo Construction Equipment. We combine this with our customer, market and application knowledge, allowing us to optimize designs and technology for specific machines and applications, considering the duty cycles, climate and environment in which they will operate.”