Perkins aftermarket and the oil filters

Perkins’ research on oil filters. Last week we published the first part of our interview to Siobhan Scott, Marketing manager at Perkins. There, she talked mainly about My Engine App and the new functionalities. Here, the focus in on the filters. What news does Perkins have in store? As we are developing brand-new engines we’re […]

Perkins’ research on oil filters. Last week we published the first part of our interview to Siobhan Scott, Marketing manager at Perkins. There, she talked mainly about My Engine App and the new functionalities. Here, the focus in on the filters.

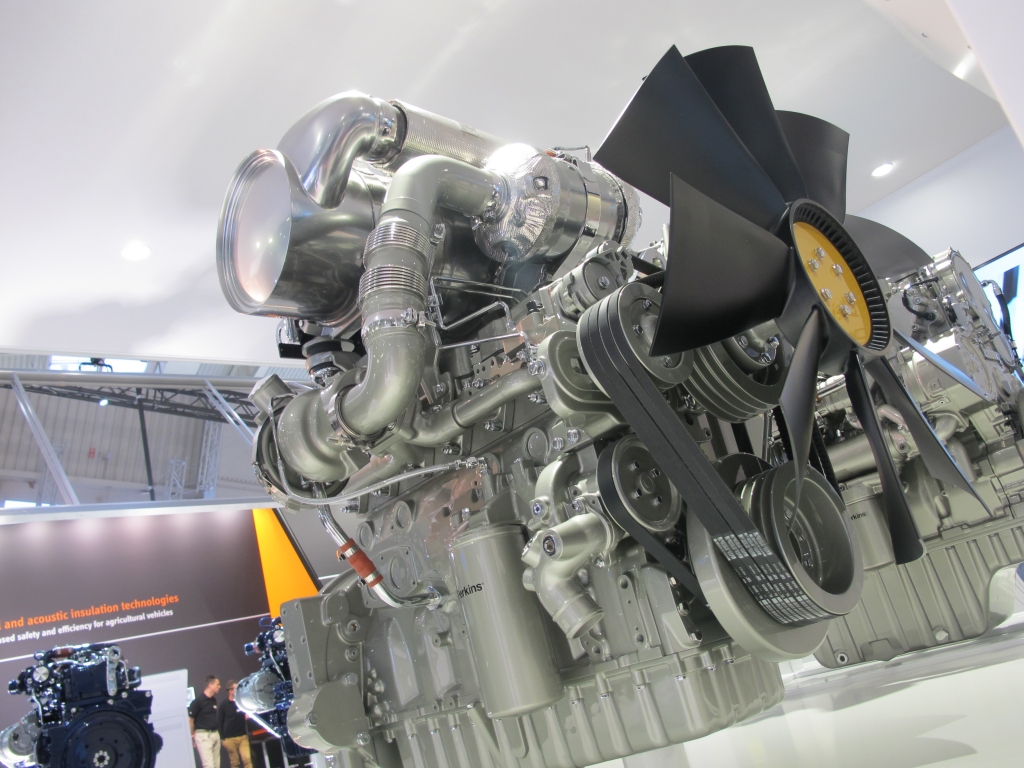

What news does Perkins have in store?

As we are developing brand-new engines we’re looking at what we can do differently for these engines to help people when they’re changing their parts and we are particularly focused on the filters.

About 20 years ago we introduced new filters called Ecoplus and we used that phrase because they were economical and environmentally friendly. These were all fuel filters and we designed them to filter the fuel very well, to protect the injectors, helping to ensure low fuel consumption, and the best engine power and performance. We make sure that the filter media doesn’t move. Where the filter media is folded we have little beads and a spiral band, so the flow of fuel does not squash the folds together. We also mould the media into the end of the filters rather than just gluing it. Most other filters are glued and it can come apart.

Also, these filters are cartridge or element filters not spin-on filters, with a lot of recyclable material in the filter and no metal outer can. And when you think about re-selling 3 million filters a year, if you could reduce the amount of material such as the metal can, you’re doing something very environmentally friendly. We have continued to increase the range of fuel filters over the last 20 years, improving the filtration capability for our higher emission engines.

PERKINS HYBRID ENGINES – PART ONE

Is there anything new in the Ecoplus range oil filters?

We introduced for the first time this year brand new oil filters into the Ecoplus range, available on Syncro 2.8 and 3.6 engines. The media has an improved performance using multi-layer material, the media stays in place using the same technology in the fuel filters, and by using an element cartridge we have removed the need for the metal can, which means less waste. And there are two key areas that we have really improved. One helps the performance of the engines, the other helps when you’re changing the filter.

So, looking at the performance first, we have introduced a very high-quality bypass valve in the filter housing, and that’s a really important part of the filter. Sometimes if you buy a low-quality old-fashioned spin-on filter, the bypass valve quality is not great.

We’ve got a reusable valve and it allows us to keep some oil available. It means that the second you turn the engine on, it has oil flowing around, straight away. So, if you turn on your engine, with a poor-quality bypass valve in some older spin-on filters there may be a few seconds before the oil starts to flow around the engine. And that’s very bad for things like turbochargers that are oil cooled. By having oil in the engine all the time we’re protecting things like the expensive to repair or replace turbocharger… So, it really helps the long-term reliability and performance of the engine, using these filters.

What can we say about maintenance?

The other great benefit is for the people who change the filters. Normally oil filters hang down, when you change the filter you take it out and a lot of oil spills out and people find they have their hands covered in oil and the mechanics hate it. They hate to go home covered in oil. It’s not nice.

THE NEWS ABOUT AFTERMARKET AT BAUMA 2019

We positioned the filter so it’s angled upright, so as soon as you start to unscrew the housing, the oil flows back into the engine, which means it’s a clean change filter, which the mechanics love. For the technicians who change the filter, the fact that it is angled and the oil flows into the engine is perfect.

Also, no special equipment is required to change the filter, the housing has a standard nut which takes a 38 mm socket or wrench.

You can only fit it one way. So, if you are a DIY (do it yourself) person it’s very simple. There’s no special tools. We’ve done everything we could to make it foolproof.