Comparisons: around 11 liters

AGCO Power, Liebherr, MAN, mtu, Scania and Volvo Penta are the protagonists of this comparison, published in its entirety in the March issue of Powertrain International

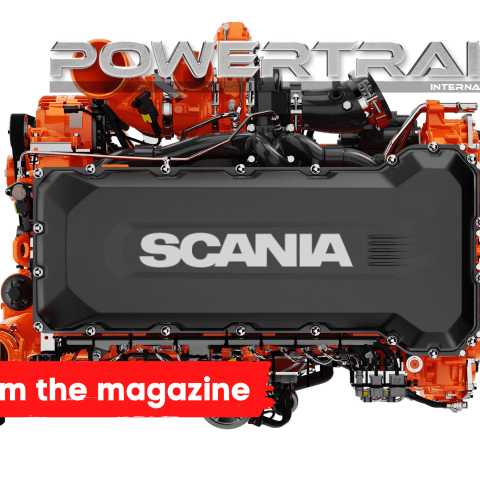

We know the Super, it is the 13-litre that competes with Weichai for the road efficiency record. A dualism that cannot be found in industrial scenarios since Scania has churned out the only monoblock capable of breaking through the 50% efficiency sound wall. “Thanks to the new exhaust gas treatment system, a reduced internal friction and an increased turbocharger efficiency, the new generation of Scania’s engines sets a new standard for efficiency in industrial and power applications. Our leadership now also extends to power solutions,” said Joel Granath, Senior Vice President and Head of Power Solutions at Scania. What perhaps not everyone remembers is that Scania has broken the spell of the trilogy: between the 9-litre and the 13-litre, without disturbing His Majesty the V8, it has introduced an 11-litre. After the season of the 11.7-litre hex cylinder, an oversized successor to an 11-litre ancestor (see box), the time has come to expand the Swedish family. The starting point is the “old” DC13, of which the 130-millimetre bore remains intact, with a solid addition of vertical thrust. In fact, the stroke increases from 140 to 160 millimetres. The result is a 10.6 litre, spread over five cylinders, like the 9-litre. Ours, in fact, is also an odd one, like its smaller brother, and is the expression of a modular platform shared with the 13-litre Super. At the time of its launch, the Gryphon promised 8% savings compared to the previous 13-litre version.

During the usual end-of-year press conference, however, Scania adjusted that figure up to 10%. “Renewable fuels and electrified vehicles will increase their share dramatically in the coming years, but we still depend on combustion engines for our daily lives. That is why Scania’s new engine is so important, as it will contribute to a substantial decarbonisation for the rest of this decade.” This was the premise and promise of Alexander Vlaskamp, Executive Vice President and Head of Sales and Marketing. As is standard practice, we put the highest-performing calibration, 368 kilowatts, in the comparison form. The available power scale starts at 202 kilowatts. The vital section of the Super family confirms the ingredients of Scania’s recent success, namely Stage IIIB, and Euro 4 onwards. The engine management system is the tested Ems, which oversees the Xoi nozzles delivery, and communicates with the variable geometry turbo. The distribution is ensured by the double overhead camshaft. Attention to flow management is one of the keys to efficiency implementation, also including the cooling development, together with the benefits of the engine block and cylinder head, and a gear transmission. The fuel filter is mounted on the engine, the additional prefilter features a water separator.

The oil cooler is integrated in the cylinder block. Integrated auxiliary braking is provided by the compression release brake (Crb), which is integrated in the engine and weighs 7 kilos.

Let’s go through the other main contestants of the competition. We have selected only the most similar displacements, i.e. in the narrow range of cubic centimetres between 9.8 and 10.8 litres. In the past, we had widened such range to 9 litres, thus including two giants of the dual stage, here interpreted as competence in both road and industrial, such as Caterpillar, Cummins, Fpt Industrial and Perkins. Moreover, the “twins” Cat and Perkins had won the Diesel Index of the comparison exactly two years before. In Turin, it is possible to find the 11-litre, namely the Cursor 11, currently destined for Iveco’s S-Way. Let’s start with the good news, even if that means starting from the end: the Diesel Index is a prerogative of the DC11, as well as the Performance Index and Compactness Index. Scania shares with the other Scandinavian company, Agco Power, the singular “odd”attitude. This is in turn a sui generis analogy, since odd for Scania means 5 cylinders, while Agco splits the cubic capacity over 7 cylinders. The result is the comparison of a 2.12-litre and a 1.4-litre barrel which in terms of stress are very similar, giving curves that are not so different and with the same piston speed. Their respective average effective pressures also get in the top rungs of the podium, demonstrating a precise engineering will.

Leaving this “ugrofinnical” dualism, what are Scania’s winning cards on the table for this comparison? Certainly, those that answer the ear worm of any engine comparison: specific torque and compactness. To translate this concept into numbers, just think of the gap with the second-placed contestant in the partial ranking of torque to displacement ratio: almost 20 percent, similarly to the gap with Rolls-Royce Power Systems’ equal displacement (10.6 litres, even if fractioned over 6 cylinders), in this case in absolute torque values (423 Nm difference).

It is instead AGCO that catches all the attention in terms of specific power, due to its 365 kilowatts spread over 7 cylinders and just 9.8 litres. With 37.1 kilowatts/litre, it leaves behind all the other competitors that, all in all, are fairly aligned, with the exception of Volvo Penta, which is weaker than in other situations. It is needless to say that we are only talking about supercharged engines, and the VGT blows loudly. There is no room for jokes here when it comes to electronic control and common rail. What we report in our conclusion is just an impression. While waiting for the drafting of the final text of the Euro 7 standard, we don’t know how ingenious the automotive manufacturers will be and what they will be adding to the industrial price lists. What is certain is that Scania has accelerated on the enhancement of endothermic engines, as far as it will be allowed by European legislators, and not only there. The impression concerns the possible massive adhesion of engines between 9 and 13 litres to hydrogen power supply. Only time will tell…

TO READ THE FULL ARTICLE CLICK HERE OR DOWNLOAD IT BELOW