Biomethane-fueled FPT F28: road to the first green harvest with New Holland and Fontanafredda

It’s time for the Biomethane-fueled F28. The innovative Fpt Industrial engine, Diesel of the Year 2020, in fact, is about to cross another milestone, thanks to the partnership with a primary Italian wine producer Fontanafredda. The project, launched with a dedicated event on the 19th of February, is based on the above-mentioned F28, installed on […]

It’s time for the Biomethane-fueled F28. The innovative Fpt Industrial engine, Diesel of the Year 2020, in fact, is about to cross another milestone, thanks to the partnership with a primary Italian wine producer Fontanafredda. The project, launched with a dedicated event on the 19th of February, is based on the above-mentioned F28, installed on two New Holland TK Methane Power crawler vineyard tractors in its NG version. During the next harvest, the New Holland tractors will take care of the precious Vigna La Rosa cru, that produces the grapes for the legendary Barolo of the same name, a wine which has been included in the Wine Spectator Top 100 of the world’s best wines.

Fpt relies on biomethane to make sustainability ture

The idea that led to the project of sustainable mobility in the vineyard is part of a broader scenario marked by sustainability and respect for the environment that Fontanafredda, run in the Langhe area by the Farinetti family, has been promoting for years. Organic growing methods, a preference for autochthonous yeasts in the cellar, reuse of water and clean energy for the Village are just some of the actions taken so far. The target has the name of a new Renaissance.

«For us, this renewal means making our land central to everything we do; this must be our overriding aim, and must lead to the creation of a great worldwide community, based on trust in others. This community will have many tools at its disposal for safeguarding our planet: ours will be wine, ‘green’ wine. Our partnership with FPT Industrial proves that together we can do more, and do it better». These words were spoken by Andrea Farinetti, who also pointed out that biomethane is not generated by the company’s processing waste, but rather comes from a safe and certified supply chain. The aim is to have an entire ‘decarbonised’ fleet available within 3 to 5 years.

Stupenengo: natural gas is today’s solution

«The partnership with Fontanafredda will enable us to again demonstrate our full support for the European Union as it guides the green transition. Our biomethane engines are as efficient and high-performing as diesels, and this renewable, sustainable fuel is the real, immediately available alternative for eliminating emissions from agricultural vehicles», added Annalisa Stupenengo, FPT Industrial CEO, insisting on the role of game changer acknowledged by many to FPT also because of the Cursor X concept. «Natural gas is a ‘ready now’ solution that allows us to welcome innovation. We already have over 55,000 NG engines at work in practical applications worldwide».

Biffali: the F28 was born modular

The use of biomethane is indeed the next step. It is the result of processing agricultural waste that costs nothing and which, indeed, it would be a cost to dispose of. A circular economy for all intents and purposes, with interesting prospects in terms of environmental, as well as economic, sustainability for farmers. «Our F28 engine was born modular and is unprecedented in this category of agricultural machinery» explains Pierpaolo Biffali, Vice President Product Engineering at FPT Industrial. «The prototypes designed together with New Holland make it possible to work in very tight spaces with performance and autonomy comparable to a traditional engine». Asked about the decision to focus on biomethane and not, for example, on electric solutions, Biffali replied that batteries, although considered a key element in the ecological transition, would not guarantee a comparable autonomy for wine growers in such a case. Biomethane appears to be a ‘ready now’ solution that is more sustainable in the short-term due to its virtuous implications in the agricultural cycle.

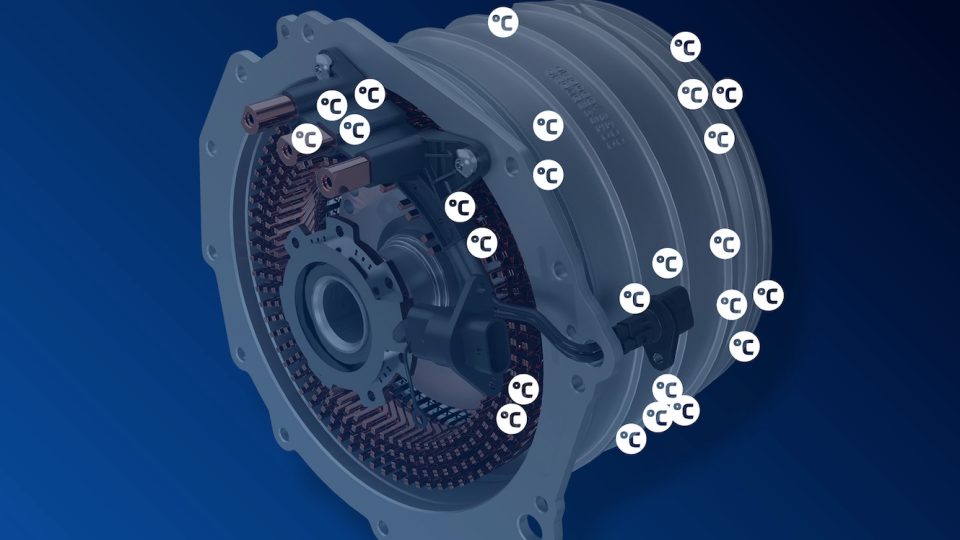

Biomethane-fueled F28 NG: 55 kilowatts of power

Moving on to more technical matters, the 4-cylinder, 2.8-litre F28 engines that will equip New Holland’s crawler tractors within the Fontanafredda vineyard will deliver 55 kW maximum power output with 330 Nm maximum torque and will be able to count on stoichiometric combustion technology as well as multipoint injection. With the EGR gone, it features a 3-way catalytic converter and is relieved of additional maintenance burdens, being free of both DPF and SCR. All to the benefit of compactness and therefore the ability to tackle rough terrain and particularly narrow rows.