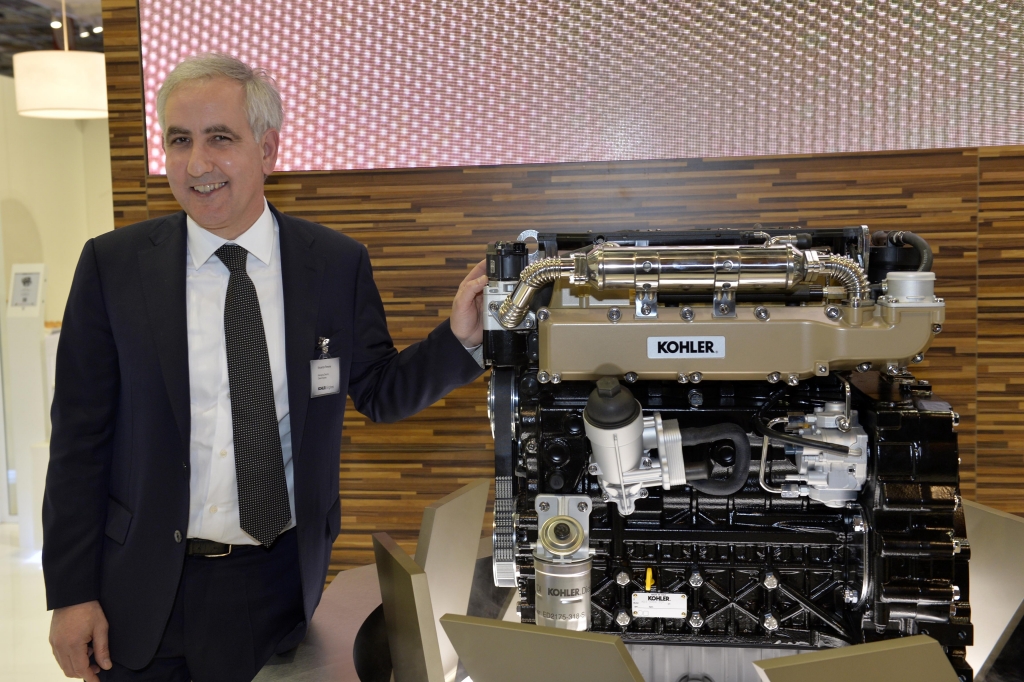

Kohler and Covid-19. A view from the inside

Kohler and Covid-19 Kohler and Covid-19, in other words the challenge of the restrictions due to the global outbreak. We asked Kohler how they’re dealing with this moment and how they’re going to get through it. Was the need of getting protective measures an obstacle to guarantee the manufacturing process? Since Kohler is a […]

Kohler and Covid-19

Kohler and Covid-19, in other words the challenge of the restrictions due to the global outbreak. We asked Kohler how they’re dealing with this moment and how they’re going to get through it.

Was the need of getting protective measures an obstacle to guarantee the manufacturing process?

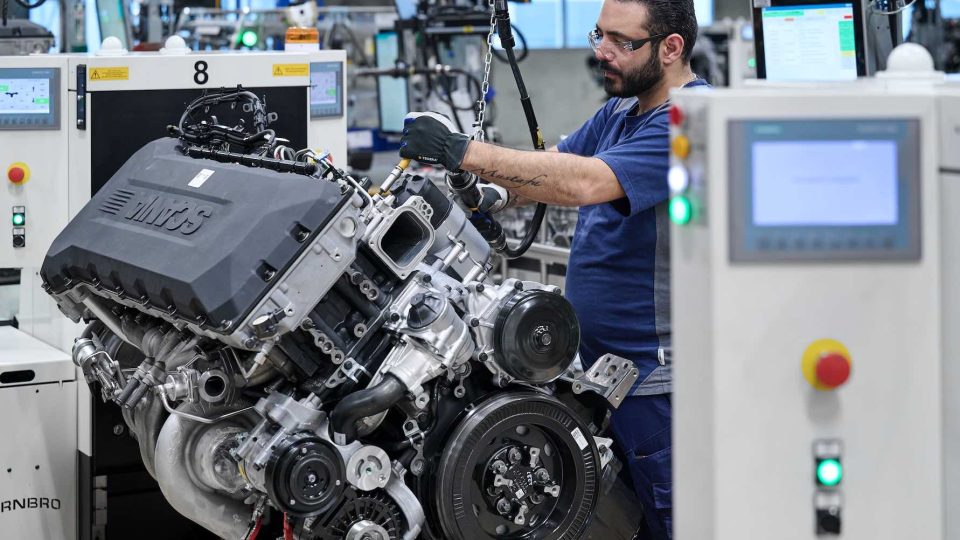

Since Kohler is a global company, we faced the challenge posed by the novel coronavirus in different periods based on the locations and the guidelines of the national governments. Kohler strength in this case is that we haven’t seen a full global stop yet, and we are confident we won’t see it in the future. We have now provided our facilities with personal protective equipment (face masks, sanitizers and infrared thermometers), despite the difficulties of retrieving such material in these days. In this case, it’s been great to see the solidarity among colleagues, especially from our Chinese colleagues who worked hard to ensure the shipments of personal protective equipment rapidly and efficiently.

How are you managing the manufacturing and shipping schedules? Do you have production facilities around the world that have not been affected in the same way as those in Europe?

The shipping schedules have been ensured by all plants even during the toughest days. Also, the Customer Service has been provided continuously by associates working remotely, and the Service & Aftermarket department has never stopped shipping genuine parts for the maintenance of Kohler’s products, especially for applications in the field that are supporting the agriculture sector. Kohler’s facilities in the US are still active because the production of generators have been judged necessary by the Authorities.

Will R&D Kohler programs slow down because of the Covid-19 issues?

The pandemic will slow down R&D programs, but we are happy it will never stop them; in fact, Kohler’s engineers are putting many efforts in working remotely to respect their schedule despite the emergency.

Due to its health origin, the current crisis is certainly different from that of 2008. However, is there, in your opinion, any shared element? And can the experience that the majority of entrepreneurs and managers have lived through at that time help them face the current moment?

In our opinion, there’s only one shared element from a corporate perspective: the reduced sales volumes. In fact, the great financial crisis was related to goods and financial tools, and didn’t directly affect the health of workers. So yes, we can leverage the experience we grew at that time, but we must adapt it to new scenarios, this will be our biggest challenge.

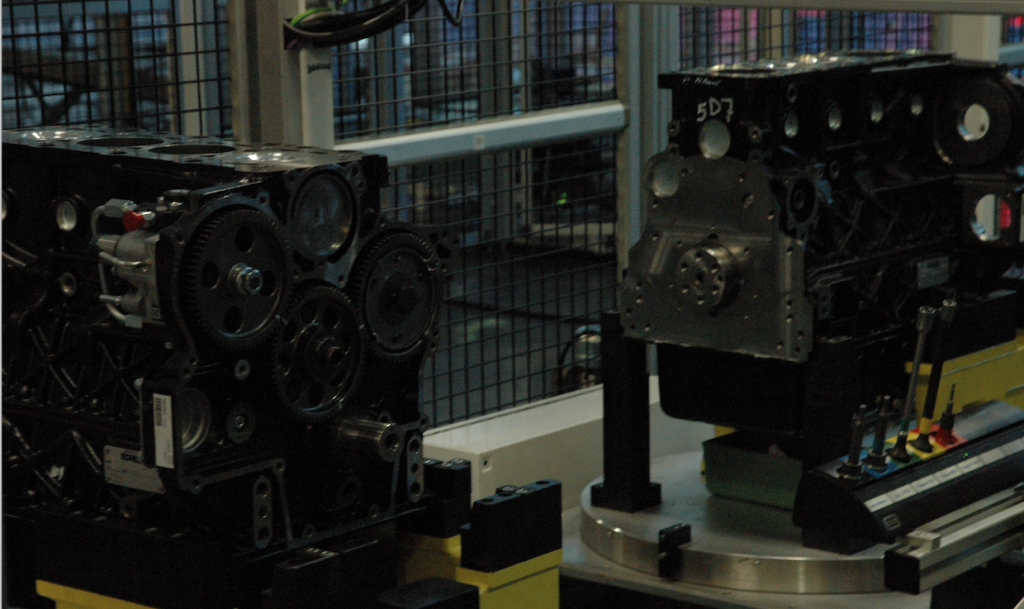

In recent years, various realities have rethought (or are rethinking) the production process according to the logic of digitization, which also involve different tasks for operators and a different allocation. Can this mitigate the negative effects of lockdown? And will a more rational distribution of human resources help resume production safely?

Physical distancing is necessary; it is fundamental to apply it in every single facility for the next months. At Kohler, we are lucky that our plants are planned to ensure that every associate owns his/her workstation. To resume the production, we’ve just adapted the shared areas (cafeterias, changing rooms, lounge areas, etc.).

How do Kohler imagine the world after the Covid-19, in terms of communication and trade events (fairs and so on)?

Covid-19 has already changed many aspects of the life of humans. That’s why we expect that changes will occur both in terms of communication and tradeshows: the good news is that the market has always changed, and we’ve always adapted. This is what we’ll do, because resilience is in Kohler associates DNA.

A question that answers a personal curiosity: could the Coronavirus trouble find a place in the recently opened Gallery of engines in Reggio Emilia?

Why not! The brand-new museum “Gallery of engines” opened last December at the diesel headquarters in Reggio Emilia, Italy, has been conceived to change and evolve, so it could be a brilliant idea to create a Covid-19 related exhibition.