Wacker Neuson WL95 and WL110, the medium wheel loaders

The Wacker Neuson WL95 and WL110 medium wheel loaders, powered by Deutz, cover a key market segment for wheel loaders, with applications ranging from classic construction sites to industrial plants.

Wacker Neuson has always focused on the construction company market. With a range of machines and equipment ranging from the world of earthmoving up to the road and concrete world. The range of wheel loaders of the German manufacturer derives from the Weidemann models, a company that is part of the Group and is a famous and appreciated manufacturer for his models widely used in agriculture. These models already made up the Wacker offer before 2007, the year in which there was the merger with Neuson Kramer which gave rise to the new and well-known current brand.

Since then, the offer of wheel loaders within the Group has essentially doubled with the offer of articulated and rigid vehicles coming from Weidemann on the one hand and from Kramer on the other. Currently, the Wacker Neuson range dedicated to the construction market consists of 14 models, with operating weights from 2,000 to 11,250 kg and powers from 18.4 to 115 kW. The two top models are the WL95 and the WL100, two wheel loaders that occupy a segment that, for Wacker Neuson, was an absolute novelty. We are in fact talking about “medium” machines with transversal uses.

Wacker Neuson WL95 and WL110, the turning point of the brand

With their entry on the market, the WL95 and WL110 marked the turning point of the brand. Especially in terms of ergonomics, design and contents. A segment in which the manufacturer was not present and which represents a very interesting potential market. Two machines that derive from the same platform but with different engines and hydraulics. And with equally marked application areas. If in fact a little more than a ton of difference in the operating weight might seem little, in reality we are talking about almost 10% of difference.

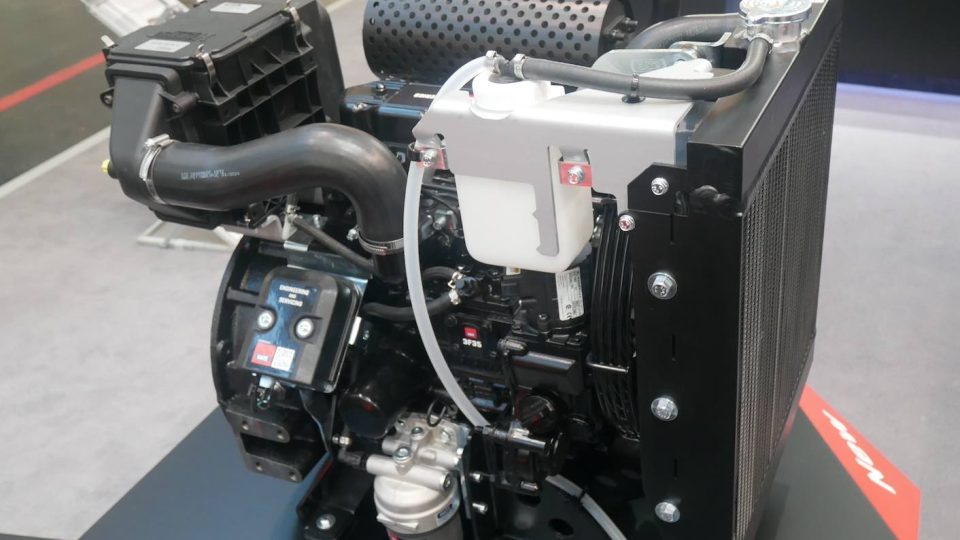

The WL95 weighs 10,390 kg while the WL110 reaches 11,250 kg. The engines are Deutz in both cases. But with the TCD 3.6 S5 for the WL95 and the TCD 4.1 S5 for the WL110, with power levels of 100 kW (136 hp) and 115 kW (156 hp), respectively. The working hydraulics provide 150 l / min for the WL95 and 180 l / min for the WL110. These values are not very far from each other but which constitute a delta that defines a precise market target. In fact, it is no coincidence that the bucket capacity is 1.55 and 1.80 cubic meters, thus defining application areas where we have the classic construction site on the one hand and handling on the other.